Steel fabrication is a critical industry that plays a vital role in construction, manufacturing, and various engineering projects. As we approach 2025, both beginners and seasoned professionals are looking to navigate the evolving landscape of doing steel fabrication efficiently and sustainably. Renowned expert in the field, Dr. Emily Carter, states, "The future of doing steel fabrication lies in embracing new technologies and sustainable practices that not only enhance productivity but also reduce environmental impact." This sentiment underscores the necessity for aspiring fabricators to equip themselves with the latest knowledge and techniques.

In this increasingly competitive market, it is essential to understand the fundamentals of doing steel fabrication while remaining adaptable to innovations. Opportunities abound for those ready to learn about advanced welding techniques, automation in fabrication processes, and the integration of green materials. Newcomers and experts alike face the challenge of staying updated with industry trends and government regulations that shape the practices of doing steel fabrication.

Ultimately, navigating the complexities of this field requires a commitment to continuous learning and a willingness to embrace change. With the right guidance and resources, individuals can position themselves to thrive in the ever-evolving world of steel fabrication as we head into 2025 and beyond.

Steel fabrication is a crucial process in various industries, encompassing the cutting, bending, and assembling of steel structures. Understanding the fundamentals of steel fabrication is essential for both beginners and experienced professionals looking to enhance their skills or venture into this domain. Key concepts include the properties of steel, various fabrication techniques, and safety protocols. Knowledge of these basics serves as a foundation for further exploration and development in the field, enabling individuals to create durable and reliable products.

The significance of steel fabrication lies in its wide range of applications, from construction to manufacturing. Steel is known for its strength, versatility, and recyclability, making it an ideal material for creating everything from bridges and buildings to intricate machinery and tools. By mastering the principles of steel fabrication, professionals can contribute to innovative designs and sustainable practices, ensuring that structures can withstand the test of time while meeting modern standards for efficiency and safety. Furthermore, understanding the importance of precision and quality control in the fabrication process ultimately leads to enhanced productivity and minimizes waste, driving the industry forward.

When starting your journey in steel fabrication, having the right tools and equipment is crucial for both beginners and experts. Essential items include a sturdy workbench, cutting tools like plasma cutters or band saws, and welding machines to join metal pieces effectively. Additionally, safety gear such as gloves, masks, and eye protection must not be overlooked to ensure a safe working environment.

Tips: Always prioritize investing in quality tools that suit your specific needs. While it might be tempting to purchase the cheapest options available, higher-quality tools tend to last longer and perform better, ultimately saving you money and time in the long run. Furthermore, taking time to organize your workspace can greatly enhance efficiency and reduce the risk of accidents.

Another must-have equipment is metal forming tools, which play a vital role in shaping steel. This includes presses, shears, and benders that allow you to manipulate metal to your desired specifications. Furthermore, consider incorporating measuring and marking tools like calipers and squares to achieve precision in your projects.

Tips: Keeping a maintenance routine for your tools and equipment is essential for maintaining their longevity. Regular cleaning, inspection, and proper storage can prevent issues and help you work more effectively.

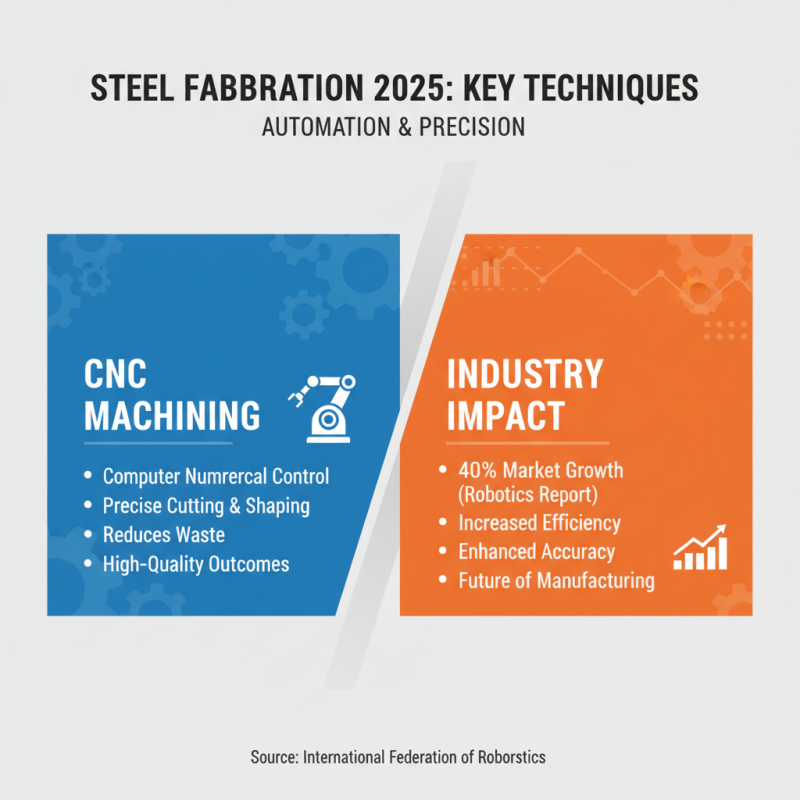

Steel fabrication is an essential process in various industries, from construction to manufacturing, and as we approach 2025, understanding key techniques and processes becomes increasingly critical for both beginners and experts. One fundamental technique is the use of Computer Numerical Control (CNC) machining, which allows for precise cutting and shaping of steel components. According to a report by the International Federation of Robotics, CNC technologies have accounted for nearly 40% of the market growth in the fabrication sector, indicating a trend towards automation that enhances efficiency and accuracy. Implementing CNC operations can significantly reduce waste and lead to consistently high-quality outcomes.

Another vital process is welding, which serves as the backbone of steel fabrication. There are several welding methods, including MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding, each suited for different applications based on material thickness and type. The American Welding Society states that the demand for skilled welders is projected to increase by 6% through 2028, underscoring the importance of mastering these techniques as they will remain relevant and in high demand. Additionally, advancements in welding technology, such as laser welding and robotic welding systems, are transforming the industry by offering faster production times and enhanced weld quality. By integrating these techniques into their projects, steel fabricators can position themselves to meet evolving market demands in the years to come.

In the steel fabrication industry, adhering to safety standards is paramount. According to the Occupational Safety and Health Administration (OSHA), construction workers face an array of hazards including falls, electrical risks, and exposure to harmful materials. Industries that prioritize safety report a significant reduction in workplace accidents, with an estimated 40% decrease in injury rates when effective safety protocols are implemented. This highlights the necessity of establishing comprehensive safety training programs, which should cover personal protective equipment (PPE) usage, machine operation safety, and emergency response procedures.

Tips: Initiate a safety briefing at the start of each workday to reinforce safety protocols and encourage open discussions about potential risks on-site.

Moreover, staying updated with the latest safety regulations can greatly enhance operational safety. The American Institute of Steel Construction (AISC) releases annual guidelines that reflect current best practices in steel fabrication. Familiarizing oneself with these changes, along with ongoing training, fosters a culture of safety and accountability within the workforce.

Tips: Invest in regular safety workshops that focus on new technologies and methodologies in steel fabrication, helping your team remain competent and confident in their skills.

Implementing these best practices not only safeguards employees but also promotes a more efficient working environment, ultimately leading to a successful steel fabrication operation in 2025 and beyond.

As the steel fabrication industry evolves, experts must continuously enhance their skills to keep pace with emerging technologies and methodologies. Research from the World Steel Association indicates that global steel demand is poised to grow by approximately 2.3% annually, driven largely by construction and infrastructure investments. This growth calls for a deeper understanding of advanced fabrication techniques, such as automated welding, CNC machining, and integration of artificial intelligence in manufacturing processes. Professionals seeking to remain at the forefront of the industry should invest in specialized training programs and certifications that focus on these cutting-edge technologies.

In addition to formal education, networking within industry-specific forums and attending workshops can provide invaluable insights into best practices and innovative solutions. Reports suggest that companies with a culture of continuous learning see productivity increases of up to 15%. Furthermore, resources like online webinars, technical papers from industry conferences, and peer-reviewed journals play a crucial role in advancing one's expertise. Engaging with these resources not only enhances technical skills but also fosters a community of practitioners who can share experiences and strategies for overcoming common challenges in steel fabrication.

As we approach 2025, fostering a growth mindset and an eagerness to learn will be essential for professionals navigating this dynamic field.