In the evolving landscape of civil engineering, the focus on steel bridge fabrication techniques is increasingly critical. According to a report by the American Institute of Steel Construction, the U.S. steel bridge market is projected to grow significantly in the next few years. The demand for sustainable and cost-effective solutions has become paramount. Integrating advanced fabrication methods can enhance efficiency and reduce project timelines.

Innovative techniques such as modular fabrication and automated welding are gaining traction. The report highlights that these methods can decrease labor costs by up to 15%. However, despite these advances, many projects still face challenges related to quality control and material supply. Concerns about material shortages and rising prices could undermine the benefits of modern fabrication.

While the future looks promising, there are areas that require reflection. The industry must address the skills gap among workers in steel bridge fabrication. Continuous training and investment in workforce development are essential for meeting future demands. Bridging these gaps will be vital for sustainable growth and innovation in the steel bridge manufacturing sector.

The field of steel bridge fabrication is set to experience significant advancements by 2026. Recent studies indicate that robotic automation will enhance precision in manufacturing. According to a 2023 industry report, automation can increase productivity by up to 30%. This is vital for meeting growing infrastructure demands.

Sustainability is another essential focus. The adoption of eco-friendly materials could reduce carbon emissions by 20% in fabrication processes. The push for greener practices is crucial, as many bridges currently have outdated frameworks. There are concerns about maintaining structural integrity while also reducing environmental impact.

Digital technologies, such as Building Information Modeling (BIM), provide better design visualization. They help bridge designers collaborate seamlessly. However, implementation can be challenging. Many firms still lack adequate training. A balance must be struck between innovative techniques and practical workforce development. This tension will shape the future of steel bridge fabrication significantly.

Innovative materials are reshaping steel bridge construction significantly. Research from the American Institute of Steel Construction shows that using advanced steel alloys can enhance durability and load-bearing capacity. These newer materials often weigh less, providing engineers with more design flexibility. For example, high-strength steel can increase a bridge's lifespan while reducing maintenance costs.

Tips: Consider the environmental impact of material choices. Some advanced alloys can be recycled, minimizing waste. This aligns construction with sustainable practices.

The integration of smart materials is also noteworthy. Sensors embedded in steel can monitor structural health in real time. This technology provides vital data, informing maintenance decisions. However, not all projects can adopt these components due to budget constraints. Limited resources may hinder progress.

Tip: Keep an eye on funding opportunities for innovative projects. Grants can provide additional financial support.

Despite these advancements, challenges remain. The adoption of innovative materials and techniques requires skilled labor. There's a gap in training, which can lead to poor implementation. Investing in workforce development is crucial for future success in steel bridge construction.

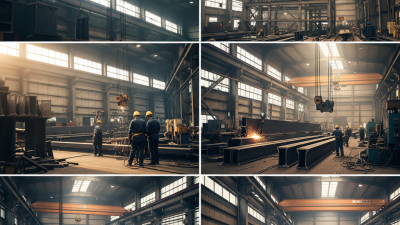

Robotic automation is revolutionizing steel bridge fabrication. By integrating robotics into processes, efficiency is significantly enhanced. Robots can handle heavy steel components with precision, reducing human error. They excel in tasks like welding, cutting, and assembly. This shift allows for faster project completion and lower costs.

However, the transition to robotics is not without challenges. Skilled operators are needed to manage and maintain automated systems. Training programs must evolve to prepare the workforce. Additionally, initial investment costs can be daunting for smaller firms. Finding the right balance between innovation and tradition is crucial.

Embracing robotic automation could reshape the future of steel bridge construction. As the industry moves forward, ongoing evaluation of these technologies is essential. Stakeholders must reflect on the benefits and drawbacks. Balancing efficiency with craftsmanship will define the next era of bridge fabrication.

The focus on sustainability in steel bridge design is growing. A recent report from the American Institute of Steel Construction states that sustainable practices lead to 20% reduced carbon emissions during fabrication. Using recycled materials is crucial. Approximately 98% of steel used in bridges can be recycled. This not only saves resources but also reduces landfill waste.

Designers often face challenges in balancing sustainability with cost and structural integrity. The material selection process can be complex. Some sustainable methods, like using lighter materials, may weaken the structure. Striking a balance is necessary to maintain safety while innovating. Additionally, maintenance practices can impact sustainability. Regular assessments are vital to ensure the longevity of bridges and minimize environmental impact.

Emerging technologies, such as 3D printing, offer new potential for sustainable steel bridge fabrication. However, the adoption of these technologies remains slow in the industry. There is a need for more education and collaboration among stakeholders. Reflecting on past practices can guide future improvements in sustainable design. Understanding these challenges is essential for achieving true sustainability in steel bridge fabrication.

Innovative steel bridge projects are on the rise. In recent years, engineers have pushed boundaries. One notable case is a project utilizing advanced modular techniques. These techniques allow sections of the bridge to be prefabricated off-site. Once ready, they are assembled on location. This method reduces labor costs and construction time, but it has challenges. Coordination between teams is crucial to ensure everything fits perfectly.

Another successful project incorporated 3D printing. This method created complex components that traditional techniques could not easily produce. The design flexibility was impressive, allowing architects to experiment. However, the durability of 3D printed elements needs careful evaluation. There are risks involved, especially with heavy loads.

Some projects implemented advanced welding techniques. These methods improved strength and reduced weight. Yet, they require highly skilled labor which can be difficult to find. Maintaining quality control is essential to avoid future issues. Each project offers lessons, highlighting the importance of balancing innovation with practicality.