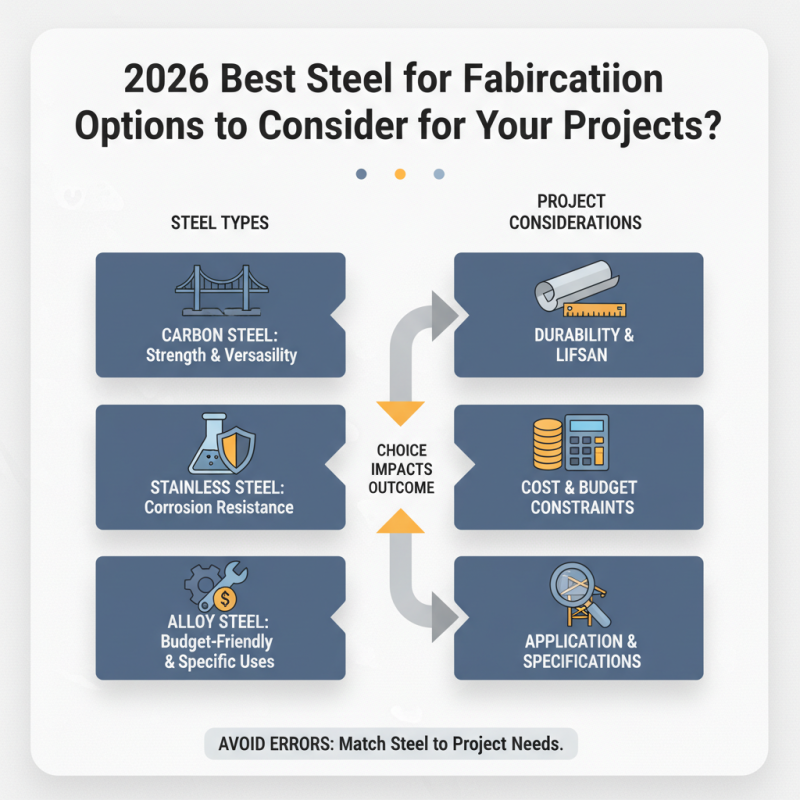

In the world of construction and manufacturing, the choice of steel for fabrication is crucial. Various types of steel offer distinct advantages for different projects. Understanding these options can enhance project efficiency and durability.

Each steel type comes with its unique properties. For instance, carbon steel is renowned for its strength and versatility. Stainless steel, on the other hand, resists corrosion effectively. However, not all projects require premium materials. Budget constraints often lead to compromises, which can challenge quality.

Fabrication needs can vary significantly. Selecting the wrong type of steel can result in structural weaknesses. Paying attention to these factors is essential. Some common errors occur when teams overlook specifications. As projects evolve, revisiting initial choices may be necessary. The right steel for fabrication can make all the difference in outcome.

When selecting steel for fabrication in 2026, understanding alloy types is essential. Various alloys offer unique properties. For instance, stainless steel is known for its corrosion resistance. In construction, mild steel is often chosen due to its weldability and lower cost.

A report by the World Steel Association highlights that structural steel usage has risen by 5% in recent years. However, nuances in alloy selection can greatly affect project outcomes. High-strength low-alloy steel provides excellent mechanical properties, but its cost may limit its use in small-scale projects.

Fabricators sometimes overlook the importance of steel grades. Not every project demands premium materials; however, choosing the right alloy can prevent failures. Standards like ASTM A992 for structural steel are critical guidelines. Yet, sometimes these standards get misinterpreted. Advanced techniques like laser cutting thrive with specific alloys, and selecting the wrong type can lead to poor results.

This chart illustrates the strength characteristics of various types of steel commonly used in fabrication projects by 2026. The data reflects the tensile strength measured in megapascals (MPa) for each steel type, highlighting the suitability for different applications in fabrication.

When considering steel options for fabrication, cost analysis is crucial. Different grades of steel carry various price points. For instance, mild steel typically costs around $0.50 per pound, while stainless steel can be upwards of $2.00 per pound. This huge price disparity impacts project budgets significantly. If a project requires corrosion resistance, stainless steel might be necessary, despite higher costs.

Additionally, the choice between hot-rolled and cold-rolled steel also influences costs. Hot-rolled steel often sees lower prices due to its easier manufacturing process. Cold-rolled steel, while more expensive, offers tighter tolerances and smoother finishes. This trade-off may lead project managers to rethink their material choices.

Another factor is fabrication needs. Specialty steels designed for specific applications can elevate costs further. For example, tool steel used for cutting applications is typically more expensive but essential for durability. A recent industry report suggests that 30% of projects overrun budgets due to unexpected material costs. This reality raises the need for careful planning and re-evaluation of needs before making final decisions.

When considering fabrication options for steel in 2026, it's vital to focus on mechanical properties like strength, ductility, and toughness. Steel's ability to withstand stress while maintaining shape is crucial. For example, high-strength steel can reach yield strengths exceeding 200 ksi. Yet, balancing strength with ductility is often overlooked. Materials that are too strong may become brittle, leading to potential failures in service.

Toughness is another key aspect. Tough steel can absorb energy before fracturing, making it ideal for high-impact applications. According to industry reports, certain alloy steels can exhibit toughness values of over 60 J, even at low temperatures. This quality is essential for projects exposed to extreme conditions. However, engineers must remain vigilant about the steel's composition. Insufficient toughness can lead to disastrous outcomes, especially in low-temperature environments.

Tips: Always evaluate the specific requirements of your project. Sometimes a smaller diameter or thinner section can offer better performance. Additionally, consider how welding might affect the overall properties of the steel. Adhering to these practices can significantly enhance your fabrications.

Sustainability is crucial in steel fabrication. As businesses focus more on environmental impact, steel selection must consider its lifecycle. According to the World Steel Association, steel is 100% recyclable. This feature makes it a prime candidate for sustainable projects.

When choosing steel, consider sourcing practices. Steel production can be energy-intensive. The Global Steel Innovations Forum states that using recycled steel can reduce energy consumption by up to 75%. However, not all recycled steel comes from sustainable sources. This raises questions on traceability and ethics in supply chains.

Certifications can also guide decisions. The LEED rating system encourages the use of sustainable materials. Steel that meets LEED standards can help projects achieve higher scores. While these certifications exist, not all manufacturers prioritize them. This inconsistency can lead to greenwashing, making it hard to discern genuinely sustainable options.

As we approach 2026, steel fabrication techniques are rapidly evolving. Advanced automation is becoming more common. Robots and software streamline operations. Factories are seeing improved efficiency, but human oversight remains crucial. Flexibility in adapting to new methods is essential. While technology enhances production, it raises concerns about job displacement.

Sustainability is another key factor. Recycled steel usage is on the rise. Eco-friendly practices reduce waste and energy consumption. However, not all businesses prioritize these measures. Striking a balance between innovation and environmental responsibility is challenging. Many companies grapple with implementation costs.

Moreover, innovations like 3D printing in steel fabrication display great potential. This method allows intricate designs previously deemed impossible. Yet, it requires specialized training and resources. As industries embrace these advancements, some might find the transition daunting. Exploring new materials and technologies opens opportunities but demands patience and adaptability.