Choosing the right steel tubing fabrication process for your project can significantly impact both the quality of your final product and the efficiency of your production timeline. As the industry evolves, various fabrication techniques have emerged, each with its own advantages and challenges. Understanding these options is essential for engineers and project managers while navigating the complexities of steel tubing fabrication. According to John Smith, a seasoned expert in the field, "Selecting the appropriate fabrication method is crucial; it not only influences the physical properties of the tubing but also affects the overall cost and delivery time."

In this context, one must consider several factors, including the intended application of the steel tubing, cost constraints, and the desired mechanical properties. Each fabrication technique — whether it be welding, bending, or machining — comes with its unique set of characteristics that can add value or introduce potential pitfalls to a project. By carefully evaluating these methods, professionals can ensure they make informed decisions that align with both their technical specifications and project goals. This article aims to guide you through the decision-making process, equipping you with the insights needed to optimize your approach to steel tubing fabrication.

When embarking on a steel tubing fabrication project, it's crucial to understand the various methods available, as each process offers distinct advantages and applications. Common fabrication processes include laser cutting, CNC machining, and welding, each being suited for different project requirements. For instance, according to a report by the Fabricators & Manufacturers Association (FMA), laser cutting has increased in popularity by over 20% in recent years due to its precision and efficiency, especially in complex designs.

Selecting the right process often depends on the project's scale, complexity, and material specifications. For smaller runs with intricate designs, laser cutting can produce high-quality results with minimal waste, while CNC machining excels in creating precision parts with consistent repeatability. On the other hand, welding remains a fundamental process for assembling larger structures, where strength and durability are paramount.

Tips: When choosing a fabrication process, consider the desired finish and tolerances required for your project. Additionally, it's wise to consult with industry experts to assess the cost-effectiveness of each method. Always align your choice with the project timeline and required material properties to optimize both performance and budget.

When selecting the right steel tubing fabrication process for your project, several critical factors must be taken into account to ensure efficiency and quality. First, consider the material specifications. Different grades of steel offer varied strength, corrosion resistance, and weldability, which can significantly influence the fabrication method. According to a report from the Steel Manufacturers Association, approximately 70% of steel tubing used in structural applications requires tailored treatments due to specific environmental conditions or load-bearing requirements. Understanding the nuances of material properties, therefore, is essential in deciding on processes such as welding, bending, or cutting.

Another vital factor is the desired end-use of the tubing. For example, structural applications might prioritize strength and durability, which could lead to choosing processes like laser cutting and precision welding. In contrast, aesthetic applications may favor methods that allow for intricate designs and finishing. A study by the American Welding Society indicated that 85% of manufacturers reported challenges in balancing quality and cost-effectiveness in their fabrication processes. Thus, aligning your project goals, including performance expectations and budget constraints, with the most suitable fabrication technique will lead to better outcomes and resource utilization.

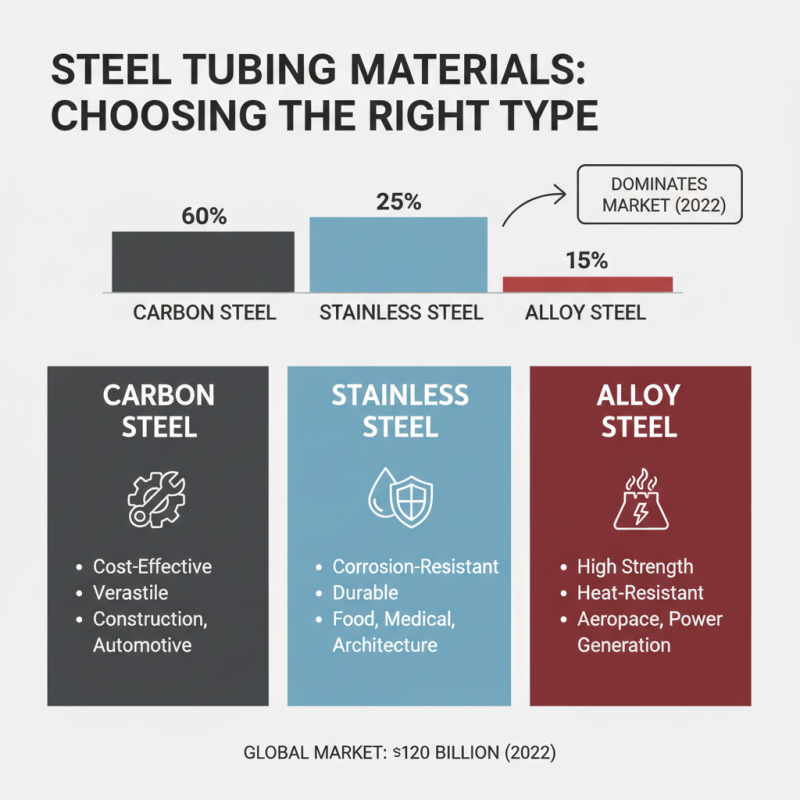

When selecting the right steel tubing material for your project, it is essential to understand the differences among various options available in the market. Steel tubing is primarily categorized into several materials, including carbon steel, stainless steel, and alloy steel. According to a report by MarketsandMarkets, the global steel tubing market was valued at approximately $120 billion in 2022, with carbon steel tubing dominating at over 60% of the share due to its cost-effectiveness and versatility in applications.

Carbon steel is favored for applications requiring strength and durability, making it ideal for structural engineering and automotive industries. On the other hand, stainless steel is increasingly gaining traction due to its corrosion-resistant properties and suitability for harsh environments, representing around 20% of the market. The 2022 Steel Fabrication Industry Report highlights that the demand for stainless steel in the construction and medical fields is expected to grow by 4.5% annually over the next five years. Meanwhile, alloy steel offers superior mechanical properties, which renders it applicable for specialized industries, such as aerospace and energy.

Each steel tubing material presents unique advantages and limitations. When making a choice, considerations such as mechanical requirements, environmental conditions, fabrication processes, and cost efficiency should drive the decision-making process. With the global focus on sustainable practices, the increasing availability of recycled steel materials also provides an avenue for eco-friendly construction practices, making steel tubing not only a robust choice but also a responsible one.

Assessing project requirements and specifications is a critical first step in selecting the appropriate steel tubing fabrication process. Each project has unique demands that influence the choice of materials, dimensions, and intended applications. For instance, according to a report by the Steel Construction Institute, approximately 60% of fabrication issues arise from misalignment with project specifications. This highlights the importance of a comprehensive assessment of the project’s requirements, including load-bearing capacities, environmental conditions, and any specific regulatory standards that must be met.

Furthermore, understanding the application of the tubing is essential, as various fabrication processes yield different material characteristics that can affect performance. A study published by the American Society of Mechanical Engineers (ASME) indicates that the selection of welding versus bending techniques can impact the strength and ductility of the final product. Projects requiring high-strength tubes might benefit from precision welding methods, whereas those emphasizing flexibility may opt for methods like cold bending. By meticulously evaluating these factors, project managers and engineers can ensure that they choose a fabrication process that not only meets the immediate needs of their project but also adheres to long-term performance criteria.

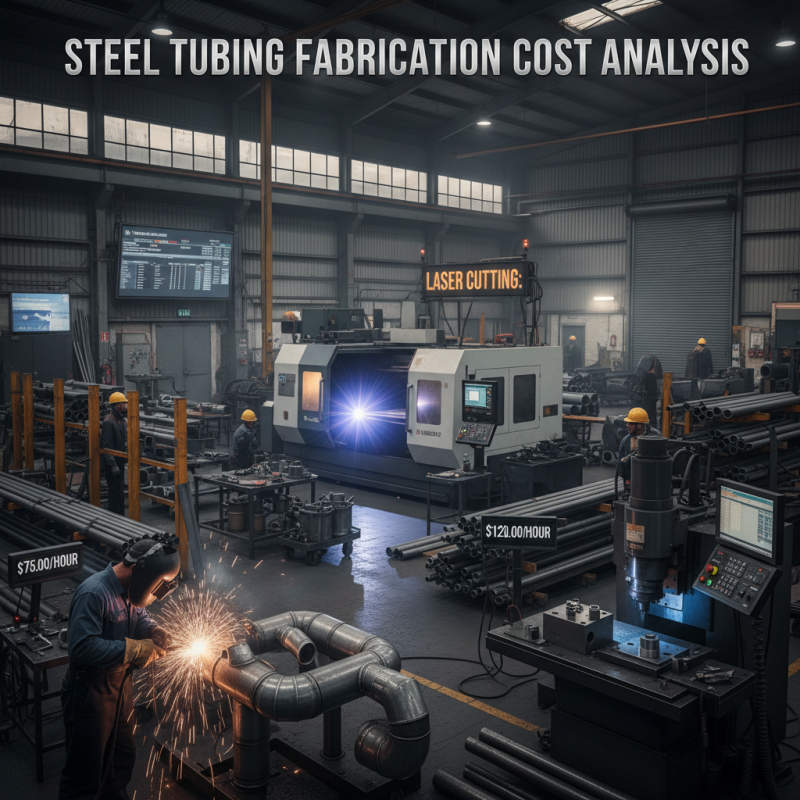

When embarking on a steel tubing fabrication project, understanding the cost associated with various fabrication processes is crucial for effective budgeting. According to the Fabricators & Manufacturers Association (FMA), the cost of fabrication can vary significantly depending on the method chosen. For instance, traditional processes such as welding and machining may range from $50 to $150 per hour, while advanced techniques like laser cutting could escalate costs to between $100 and $200 per hour. This price fluctuation highlights the need for a comprehensive cost analysis tailored to project specifications.

In addition to hourly rates, factors such as material quality, complexity of design, and project scale play pivotal roles in the overall budget. A report by the American Institute of Steel Construction (AISC) indicates that approximately 40% of total fabrication costs stem from labor, emphasizing the importance of selecting capable and efficient fabricators. Furthermore, understanding the supply chain dynamics, including material sourcing and shipping costs, can mitigate unexpected financial burdens. By incorporating precise cost analysis during the planning phase, project managers can make informed decisions about the fabrication process that align with both financial and operational goals.