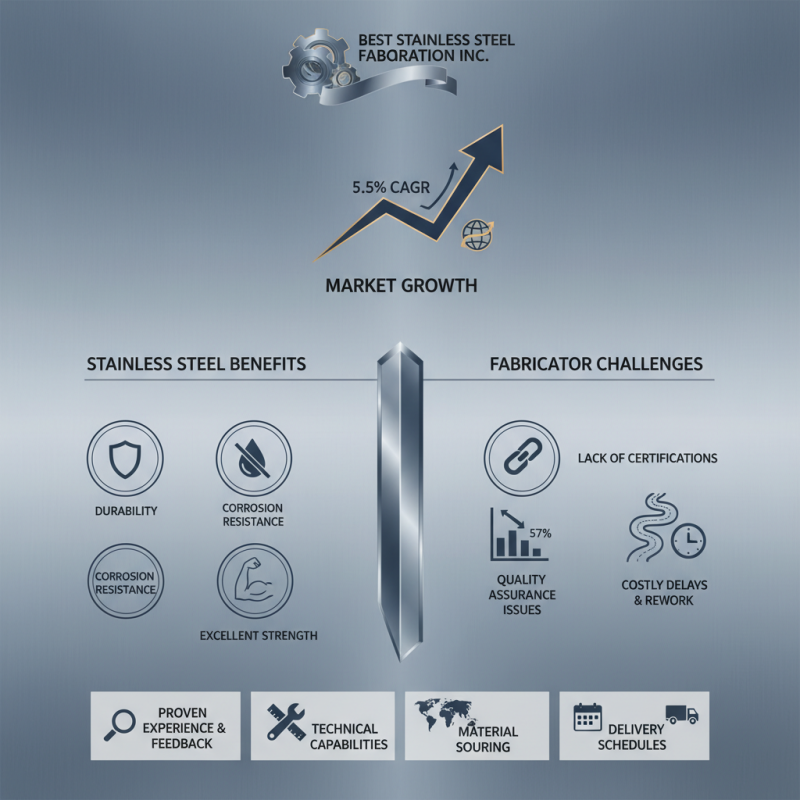

When it comes to finding the right stainless steel fabrication inc, making an informed choice is vital. The global stainless steel market is projected to grow at a CAGR of 5.5% through the next few years. This growth creates more options but also increases complexity for buyers. It’s crucial to grasp how different companies can impact your projects.

Stainless steel offers durability, corrosion resistance, and excellent strength. However, not all fabrication companies are created equal. Many may lack the necessary certifications or fail to meet industry standards. According to a recent survey, 57% of fabricators reported challenges in quality assurance. These discrepancies can lead to costly delays and rework.

Choosing a stainless steel fabrication inc requires careful research. Look for companies with proven experience and positive client feedback. Consider their technical capabilities, material sourcing, and delivery schedules. Engaging in this process can reveal flaws in potential partners that may not be obvious at first glance. Therefore, take the time to reflect on your needs and the fabricator’s offerings before making a decision.

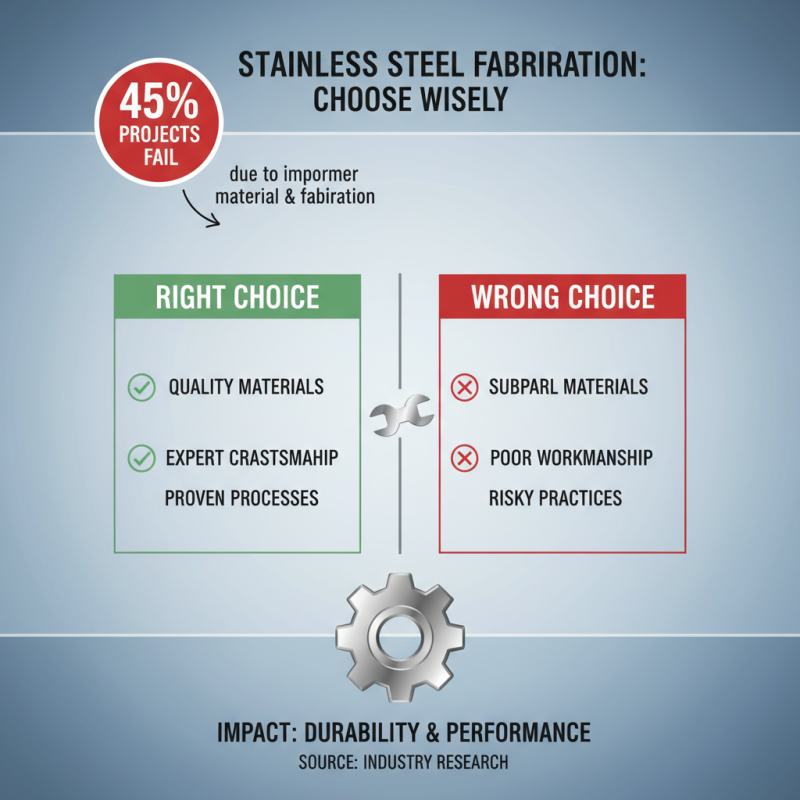

Choosing the right stainless steel fabrication company is crucial. Quality of materials and craftsmanship directly affects the final product. According to industry research, nearly 45% of projects fail due to improper material selection and fabrication processes. This statistic underscores the importance of thorough evaluation.

When selecting a company, consider their experience and expertise. A company with over a decade in the field usually demonstrates reliability. They'll possess the necessary skills to handle complex designs and specialized requirements. However, be wary of companies that play up their experience without providing case studies or examples. Not every firm with years of history delivers quality work.

Moreover, consider the technology they use. Advanced CNC machines and fabrication tools enhance precision and efficiency. Reports indicate that companies using state-of-the-art technology can produce up to 30% more accurate components. Yet, technology alone is insufficient; the skill of the technicians remains vital. An overly reliant workforce may struggle with unexpected challenges. Ask to see their fabrication process to ensure they balance technology with skilled craftsmanship.

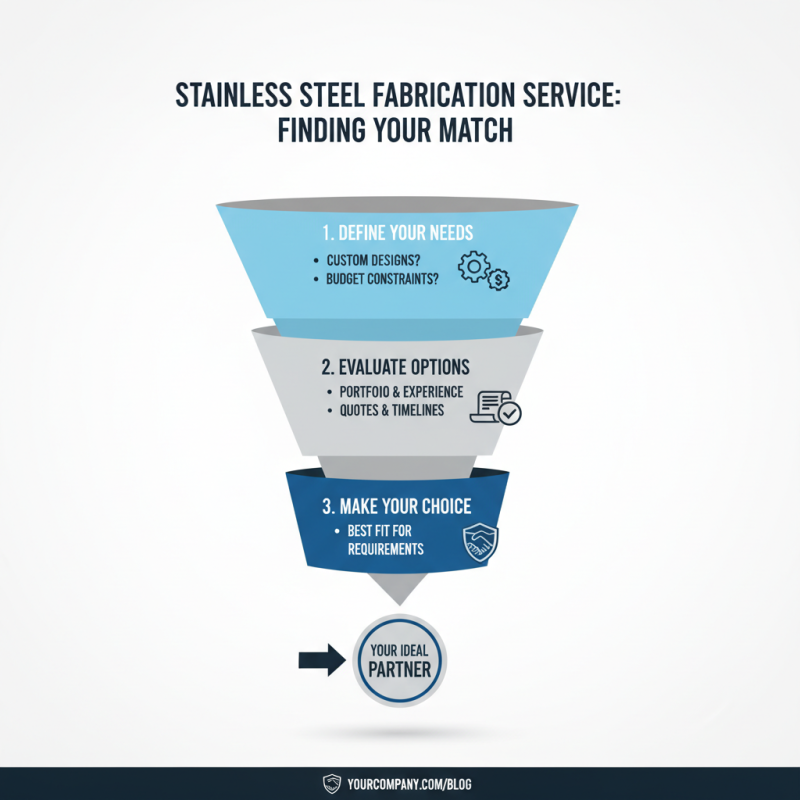

When selecting a stainless steel fabrication service, it is vital to understand your specific needs. Are you looking for custom designs? Do you have budget constraints? Defining your requirements will help narrow down your options.

Tips: Write down your goals. Identify key features you'd like. Consider the scale of your project.

Remember, not all fabricators are the same. Some may excel in large-scale projects, while others might focus on intricate designs. Reflect on the complexity of your requirements. Ensure the selected fabricator has experience in your specific area.

Tips: Ask for samples. Review previous work. Check client testimonials.

Communication is essential. Clearly express your vision and ask questions. Misunderstandings can lead to costly errors or delays. Being specific about your needs will prevent issues later on.

When selecting a stainless steel fabrication provider, experience and expertise are crucial. Look for companies with a solid track record. Check how long they have been in the industry. Longevity often indicates reliability and skill. A provider with years of experience can navigate challenges better than a newcomer. They might have encountered various projects, leading to enhanced problem-solving abilities.

Evaluate their qualifications and training. Skilled fabricators should have specific certifications. These signify adherence to industry standards. Ask about the team’s experience too. A well-trained staff can make a significant difference in project outcomes. Some providers might emphasize quantity over quality. This can lead to mistakes. That’s where you need to be cautious.

Engage with past clients if possible. Their feedback can provide insights into the provider’s expertise. Were they satisfied? Did the provider meet deadlines? Quality fabricators value their clients and communicate well. Yet, not all projects will go smoothly. Some might face delays or budget issues. This is an area for self-reflection. What can you learn from these experiences to manage future projects better? It's essential to weigh these factors carefully before making a decision.

When selecting a stainless steel fabrication company, the materials and techniques used are crucial. High-quality stainless steel offers durability and resistance to corrosion. You should ensure that the company sources premium materials for its projects. Verify the type of stainless steel they use. Check if they utilize 304 or 316 grades, as these are commonly known for their excellent properties.

Ask about the fabrication techniques employed. Methods like laser cutting and TIG welding are often more precise. Precision affects the final product's durability and appearance. Inquire about the quality checks in place. Companies committed to quality often have robust inspection processes.

Tip: Request samples of previous work. This helps gauge craftsmanship levels. Consider asking for references from past clients as well. Remember, a company's reputation often reflects its quality.

Be cautious of companies that promise quick turnarounds. Fast production can compromise quality. Take the time to evaluate their portfolio. Look for variations in design and complexity. These factors reveal the company's versatility and skill level. Effective communication during the selection process is essential to ensure your needs are understood.

When selecting a stainless steel fabrication company, reading reviews is essential. Studies show that 87% of consumers rely on online testimonials before making a decision. These reviews reveal customer experiences and highlight areas of satisfaction or concern. Pay attention to patterns in feedback, as these can indicate consistent quality or recurring issues.

Many potential customers report frustration with unresponsive services. Some fabrication companies may promise quick turnarounds but fail to deliver. A recent survey indicated that 30% of clients experienced delays beyond agreed timelines. This can lead to project setbacks. Look for reviews that mention timely communication and reliability. Engaging with customers through platforms like social media could shed light on a company's responsiveness.

Reviews often reflect the actual craftsmanship of the products. Close to 40% of reviews focus on the build quality and attention to detail. A company may be technically skilled but may overlook aesthetic aspects. Inspect photos shared by past clients. This will give a clearer picture of what to expect. A blend of positive and negative feedback can guide you to a choice that best suits your needs.

| Criteria | Rating (1-5) | Customer Feedback |

|---|---|---|

| Quality of Work | 5 | Exceptional quality and attention to detail. |

| Customer Service | 4 | Responsive and helpful, but slightly slow during peak times. |

| Timeliness | 4 | Generally met deadlines, with occasional delays. |

| Pricing | 3 | Competitive pricing, but some hidden fees noted. |

| Overall Satisfaction | 4 | Most customers would recommend this service. |