In the world of steel fabrication, maximizing efficiency is crucial. The use of a CNC machine can significantly enhance production rates. CNC machine steel fabrication combines precision with speed, achieving high-quality results. However, this process is not without its challenges.

Many fabricators overlook the importance of proper machine settings. Inaccurate configurations can lead to wasted materials and time. Additionally, understanding tooling options is vital. The wrong tools can hinder productivity and increase costs. Operators must be skilled and well-trained, as their expertise directly influences the outcome.

Efficiency also stems from regular maintenance. Neglecting this aspect can result in machine failures or inaccuracies. A well-maintained CNC machine delivers consistent performance. Embracing best practices in CNC machine steel fabrication ensures a balance between quality and efficiency. It's not just about speed; it’s also about getting it right the first time.

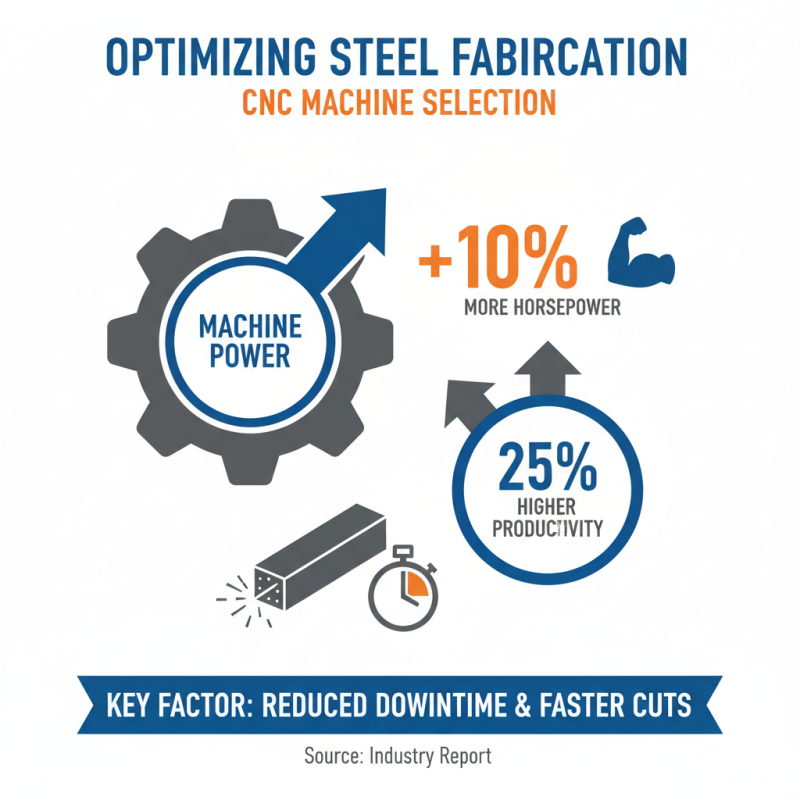

When selecting CNC machines for steel fabrication, several key factors significantly impact efficiency. The machine's power is essential. A machine with higher horsepower can cut through thicker steel more quickly, reducing downtime. According to a recent industry report, machines with 10% more horsepower can achieve up to 25% higher productivity rates.

Another critical aspect is the type of control system. Advanced CNC systems allow for greater precision. They can handle complex geometries and multi-axis movement smoothly. Research indicates that adopting modern control systems can decrease error rates by 30%. This precision translates to less waste material and substantial cost savings.

Moreover, the choice of tooling cannot be overlooked. Using the right tooling materials and geometries ensures efficient cutting and longer lifespan. However, many fabricators still struggle with the optimal selection. A misstep here can lead to reduced tool life and increased maintenance. Frequent assessments of tooling performance are crucial, yet often neglected in the hustle of production. Emphasizing the importance of tool maintenance can foster a more efficient workflow.

CNC programming plays a crucial role in steel fabrication. Understanding various techniques helps in maximizing efficiency. Knowing how to adjust feed rates can greatly impact productivity. Programming with precision ensures less material wastage.

When setting up your CNC machine, pay attention to tooling selection. The right tool can significantly enhance cutting processes. Keep in mind that tool wear is inevitable, and regular checks are essential. Adjusting tool paths can lead to better outcomes and smoother operations.

It’s important to regularly review your programs. Mistakes or outdated methods can hinder performance. Analyze your output for areas needing improvement. Experiment with different programming styles to discover what works best for your projects. This reflective approach can lead to surprising advancements in your steel processing efforts.

| Tip | Description | Benefit |

|---|---|---|

| Optimize Tool Paths | Use advanced software to plan efficient tool paths that minimize machine movement. | Reduces machining time and improves surface finish. |

| Select Appropriate Feed Rates | Adjust feed rates according to material type and thickness. | Enhances tool life and material removal rate. |

| Routine Maintenance | Establish a maintenance schedule for CNC machines to prevent breakdowns. | Ensures consistent performance and longevity of equipment. |

| Use Cutting Fluid Effectively | Choose the right cutting fluid for each specific operation to minimize heat and wear. | Improves machining quality and tool life. |

| Implement Simulation Software | Use simulation tools to visualize machining processes before executing. | Reduces risk of errors and allows for process optimization. |

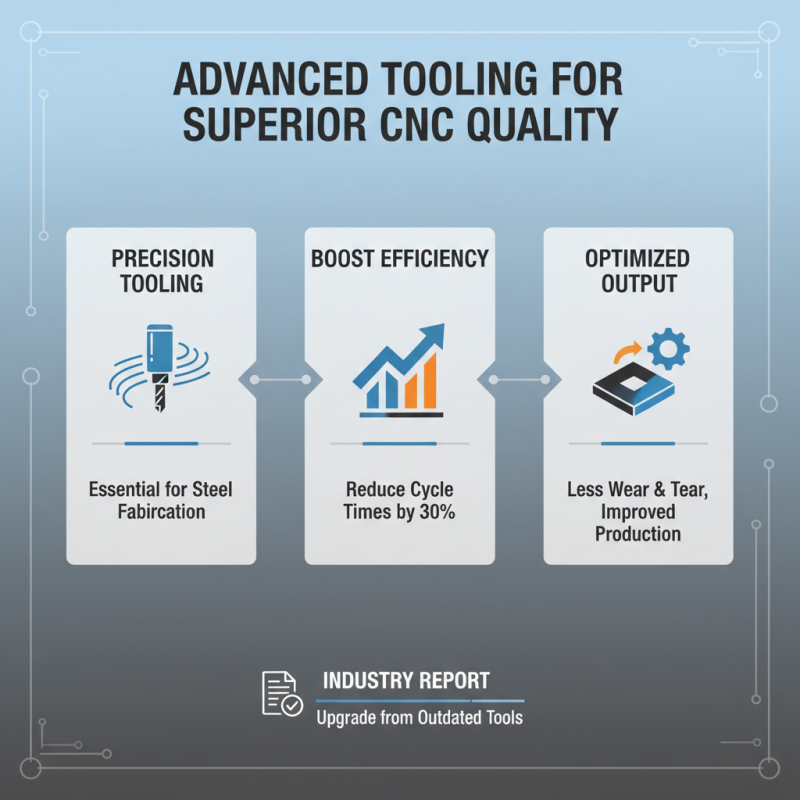

When enhancing CNC machining quality, advanced tooling strategies play a critical role. Precision tooling is essential for tackling steel fabrication efficiently. According to a recent industry report, the right tool selection can reduce cycle times by up to 30%. Not every shop utilizes high-quality tools. Many still rely on outdated options that lead to wear and tear, affecting output.

Implementing advanced coatings on cutting tools can significantly boost performance. Studies show that tools with specialized coatings can maintain their edge longer. They resist wear better than non-coated alternatives. This leads to more consistent production quality. However, not all machinists understand the importance of tool maintenance. Regular checks can prevent potential failures and unplanned downtime.

Operators should also invest time in tool path optimization. Ineffective paths lead to unnecessary wasted material. This inefficiency can inflate costs and prolong production times. While automation and software solutions offer great potential, many shops hesitate to adopt them fully. This reluctance can hinder growth and innovation. Every fabrication shop should assess its tooling strategies regularly to remain competitive. A commitment to continuous improvement is vital in this constantly evolving industry.

In the realm of steel fabrication, automation plays a crucial role in enhancing CNC machine productivity. Automated CNC machines can perform tasks without constant human intervention. This not only speeds up the fabrication process but also reduces the likelihood of errors. However, relying solely on automation can sometimes lead to missed adjustments or over-reliance on programmed settings.

Efficient steel fabrication involves knowing when to integrate manual oversight. Operators should conduct regular checks on automated systems. This ensures any anomalies are caught early. It’s essential to train personnel to understand both the technology and the materials. A blend of skills can drive better results.

Tips for improving productivity include maintaining equipment regularly. Ensuring that machines are calibrated correctly saves time in production. Another tip is to optimize tool paths for efficiency. Streamlining machining paths leads to reduced cycle times. Lastly, consider implementing software tools for real-time monitoring. This can highlight inefficiencies quickly and help with timely interventions.

CNC machining in steel fabrication is evolving rapidly. Industry standards focus on precision and efficiency. Proper calibration of CNC machines is crucial. It minimizes errors and maximizes output quality. Regularly reviewing machine settings helps ensure consistency. However, many operators overlook this step.

Best practices include utilizing high-quality tools. Dull or damaged bits lead to poor finishes. Operators sometimes rush this part, impacting overall results. Tool wear can often go unnoticed. Routine checks can prevent unexpected failures. Ensuring the right feed rate enhances productivity. Yet, it's common to notice that operators push speeds too high, risking damage.

Choosing the right software is vital for CNC operations. Many users struggle with outdated programs. This can hinder the design process. Training personnel on new technologies is essential. Yet, many facilities still lack adequate training sessions. Investing in staff development pays off in the long run. Regular feedback loops among team members can drive improvements. Creating a culture of continuous learning can elevate overall performance.