In the world of industrial manufacturing, a stainless steel fabrication shop plays a critical role. These facilities specialize in transforming raw stainless steel into usable products for various industries, from construction to automotive. As John Smith, an industry expert, once said, "Without stainless steel fabrication shops, modern infrastructure would face significant challenges."

The importance of a stainless steel fabrication shop cannot be overstated. They provide durability and resistance to corrosion, making stainless steel a favored choice for many applications. Skilled workers at these shops use advanced techniques to ensure precision and quality in every piece they create. However, one must recognize that not all shops maintain the same standards. Some may cut corners in materials or craftsmanship, leading to subpar results.

Moreover, the dynamic nature of this industry brings challenges. The demand for innovative designs requires constant adaptation. Many shops struggle to keep pace with technological advancements. Balancing quality, cost, and efficiency remains an ongoing challenge for fabricators. By reflecting on these complexities, we can better appreciate the vital role stainless steel fabrication shops hold in our economy.

Stainless steel fabrication is a process that involves shaping and assembling stainless steel into various products. This technique employs different methods, such as cutting, welding, and bending. Each method plays a crucial role in achieving the desired final product. Skilled technicians operate equipment to ensure precision in each piece they create.

Precision is essential, but imperfections can happen. Misalignments may occur during the welding process. Sometimes, the finish may not be as smooth as anticipated. Despite these challenges, the advantages of stainless steel fabrication are clear. The material's resistance to corrosion makes it a popular choice in many industries. Its durability and low maintenance needs contribute to its appeal.

Fabrication shops often focus on custom solutions. This means that designs can vary significantly. Each project may present unique challenges. Fabricators must adapt their techniques accordingly. Continuous improvement is vital in this field because different clients need different outcomes. Therefore, learning from mistakes and refining processes is part of the journey in stainless steel fabrication.

Stainless steel fabrication is integral to various industries. These shops use a mix of processes to create products from stainless steel. Key processes include cutting, shaping, welding, and finishing. Each step demands precision and skilled labor. For instance, advanced laser cutting methods ensure clean edges and accurate dimensions. Yet, these machines require regular maintenance to avoid errors.

Welding is another vital process. It joins metal pieces together, creating strong bonds. Different techniques like TIG and MIG welding are common. They each have pros and cons. Sometimes, the choice of welding method leads to weaknesses in the final product. Finishing processes such as polishing and grinding enhance surface quality. However, achieving a perfect finish can be challenging, needing multiple tries.

Quality control is essential throughout these processes. Inspections ensure the final products meet set standards. Mistakes can be costly, leaving fabricators to reconsider their practices. Communication among workers is crucial, as misunderstandings can lead to flaws. Each project presents unique challenges, requiring continuous learning and adaptation within the fabrication shop.

| Process | Description | Importance | Applications |

|---|---|---|---|

| Cutting | The process of cutting stainless steel into desired shapes and sizes using various methods such as laser, plasma, or water jet cutting. | Essential for achieving precise dimensions and clean edges, which are critical for further fabrication. | Manufacturing components for appliances, automotive parts, and construction materials. |

| Welding | Joining together pieces of stainless steel using heat and/or pressure, often with filler material. | Creates strong, durable joints that are crucial for structural integrity. | Construction, machinery, and pipeline industries. |

| Bending | Shaping stainless steel sheets or bars through the application of force using bending machines. | Allows for the creation of angled components and structural supports. | Furniture fabrication, architectural elements, and industrial equipment. |

| Finishing | Processes such as polishing, grinding, and coating to enhance surface quality and appearance. | Improves corrosion resistance and aesthetic appeal of stainless steel products. | Kitchen appliances, medical equipment, and decorative elements. |

| Assembly | Combining various fabricated parts into a complete product through methods such as fasteners or adhesives. | Final step to create functional products from fabricated components. | Equipment manufacturing, automotive assembly, and modular constructions. |

Stainless steel fabrication plays a vital role in several industries. Its durability and resistance to corrosion make it a preferred choice for construction, automotive, and food processing sectors. In construction, stainless steel beams and panels provide robust support. They withstand harsh environments and require less maintenance compared to other materials. This can save both time and money in the long run.

In the automotive industry, stainless steel is used for exhaust systems. These systems endure extreme temperatures and corrosive elements. They must maintain performance while having a long lifespan. Fabrication methods enable precise designs that fit various models. Meanwhile, the food processing sector relies on stainless steel for hygiene. Equipment must be easy to clean and resistant to bacteria. However, achieving perfect hygiene can be challenging, requiring constant vigilance.

Despite these advantages, challenges persist. Not all stainless steel grades are equal. Choosing the right one for specific applications is crucial. Sometimes decisions are made based on cost rather than suitability. This can lead to issues down the line. Hence, understanding the material's properties is important for success.

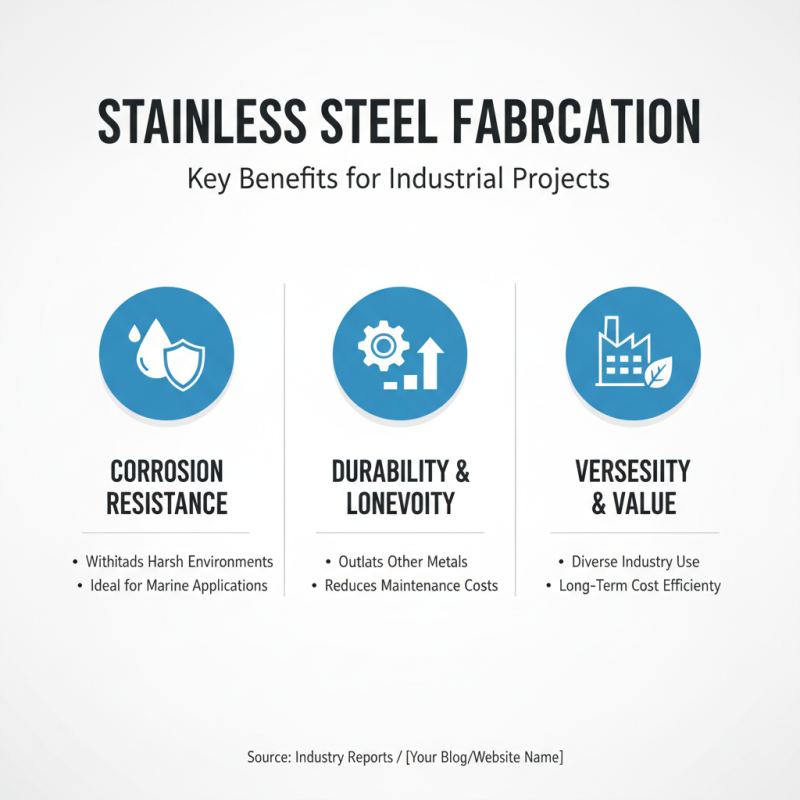

Stainless steel fabrication is a vital process in various industries. Choosing stainless steel for fabrication projects comes with numerous benefits. One prominent advantage is its resistance to corrosion. This material withstands harsh environments. For example, in marine applications, stainless steel often outlasts other metals. This durability ensures longevity, reducing maintenance costs.

Another significant benefit is the aesthetic appeal of stainless steel. Its shiny surface adds a modern look to products. Restaurants and kitchens commonly use stainless steel for equipment and fixtures, enhancing cleanliness and style. However, the sleek appearance can be marred by scratches or dents, which require careful handling.

Furthermore, stainless steel is incredibly versatile. It can be molded into various shapes and sizes. This flexibility allows designers to innovate without compromise. Nonetheless, working with stainless steel can present challenges. Fabrication requires skilled labor and specialized tools. Not every shop is equipped to handle these materials effectively.

In the world of stainless steel fabrication, skilled workers are the backbone of success. According to the Fabricators and Manufacturers Association, over 80% of manufacturing companies report a shortage of skilled workers. Many businesses struggle to fill crucial roles. The demand for expertise in stainless steel fabrication continues to grow. Skilled workers ensure precision, quality, and efficiency in every project.

The process of fabrication is intricate. It requires specialized training and hands-on experience. These skilled individuals operate sophisticated machinery. They interpret blueprints and ensure that every piece meets stringent specifications. The precision in their work directly affects the final product. A study by the American Welding Society highlights that lack of training leads to costly mistakes. In this field, errors can be both expensive and dangerous.

Moreover, the role of skilled workers goes beyond just operations. They mentor the next generation. Many shops have apprenticeship programs, yet participation remains low. Encouraging young talents to join this field is vital. The success of stainless steel fabrication shops hinges on this relationship. Investing in training can foster a new wave of skilled workers. Without them, the industry faces a daunting future.