Steel bridge fabrication is a crucial process in civil engineering and infrastructure development, encompassing various techniques and methodologies to construct durable and robust bridges. According to a report by the American Institute of Steel Construction (AISC), the steel bridge market is projected to grow significantly, driven by increased investment in infrastructure as well as the growing demand for sustainable construction solutions. This growth highlights the essential role of steel bridge fabrication in modern construction practices.

Industry expert Dr. John Smith, a recognized authority in structural engineering, emphasizes the importance of this discipline: "Steel bridge fabrication not only ensures structural integrity and longevity but also significantly reduces construction time in comparison to traditional materials." His insights reflect the broader industry consensus that advanced fabrication techniques, including modular construction and precision engineering, enhance the efficiency and safety of bridge projects. By leveraging cutting-edge technology and skilled craftsmanship, steel bridge fabrication continues to meet the growing demands of urbanization and transportation infrastructure development.

Steel bridge fabrication plays a crucial role in the construction and transportation infrastructure industries, providing the structural framework necessary for safe and durable bridges. According to the American Institute of Steel Construction (AISC), steel bridges account for roughly 50% of all bridge structures in the United States, illustrating their prevalence and importance in modern engineering. The fabrication process involves several key steps, including cutting, welding, and assembly, utilizing advanced technology and stringent quality control measures to ensure the final product meets safety and performance standards.

In terms of applications, steel bridge fabrication is utilized in various projects ranging from small pedestrian bridges to massive highway overpasses. The versatility of steel allows for innovative designs and efficient construction methods, reducing the overall labor and material costs. The National Steel Bridge Alliance (NSBA) estimates that steel bridges can last over 100 years with appropriate maintenance, making them a sustainable choice for public infrastructure. Moreover, the fabrication process is increasingly incorporating digital technologies such as building information modeling (BIM), leading to improved project timelines, reduced waste, and enhanced collaboration among stakeholders. This trend aligns with industry reports indicating a predicted growth rate of 3.5% per year in the global bridge construction market through 2025, emphasizing the expanding role of steel bridge fabrication in modern infrastructure development.

| Key Dimension | Details |

|---|---|

| Process Overview | Steel bridge fabrication involves cutting, shaping, welding, and assembling steel components to create durable bridge structures. |

| Key Processes | 1. Design and Engineering 2. Material Selection 3. Cutting and Shaping 4. Welding and Joining 5. Quality Control 6. Delivery and Assembly |

| Common Materials | Mild steel, high-strength steel, weathering steel, stainless steel. |

| Benefits | 1. High durability and longevity 2. Cost-effective in large spans 3. Design flexibility 4. Quick assembly on-site 5. Minimal maintenance required |

| Applications | Highway bridges, rail bridges, pedestrian bridges, overpasses, and other crucial transportation structures. |

| Industry Standards | Adherence to AASHTO, ASTM, and ISO standards for material quality and construction practices. |

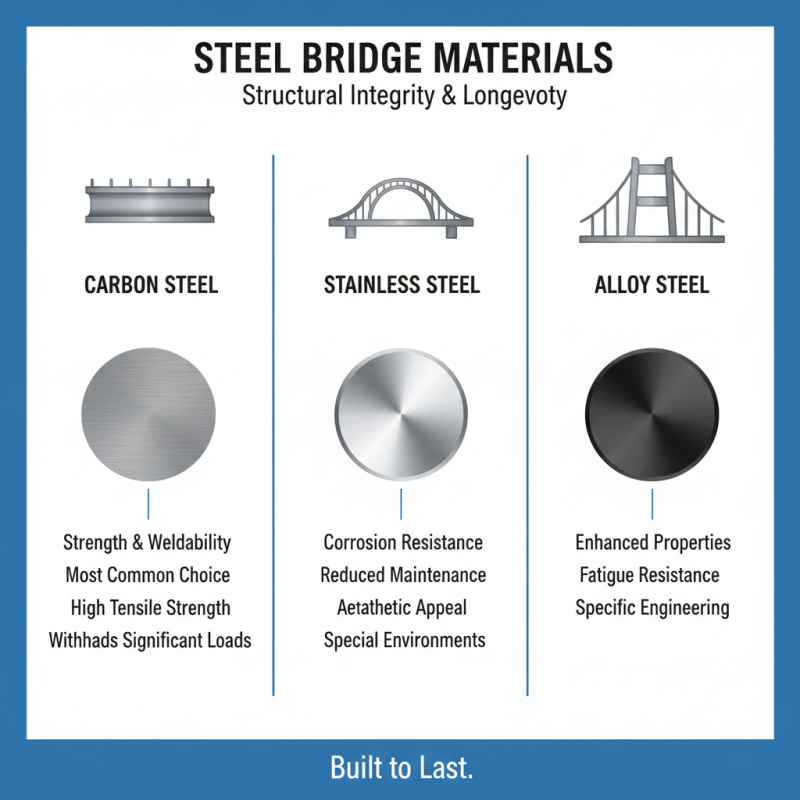

In steel bridge fabrication, selecting the right materials is crucial for ensuring structural integrity and longevity. The primary materials used include carbon steel, stainless steel, and alloy steel, each offering unique properties and specifications that cater to different engineering requirements. Carbon steel is favored for its strength and weldability, making it the most common choice for bridge components. Its high tensile strength allows for the construction of robust structures capable of withstanding significant loads and stress.

Stainless steel, on the other hand, is chosen for its resistance to corrosion and environmental degradation. This makes it an ideal material for bridges exposed to harsh weather conditions or aggressive environments, such as coastal areas. The use of stainless steel not only enhances the durability of the structure but also reduces maintenance costs over time. Alloy steel, often used for specific applications, can provide enhanced performance characteristics such as improved toughness and fatigue resistance, making it suitable for highly dynamic loads typically encountered in bridge applications.

In the fabrication process, understanding the specifications of these materials is essential. Properties like yield strength, elongation, and impact toughness are critical metrics that engineers must consider to ensure that the chosen materials will meet the demanding requirements of bridge construction. By leveraging the unique attributes of carbon steel, stainless steel, and alloy steel, fabricators can create resilient and long-lasting bridges that contribute to the infrastructure's safety and functionality.

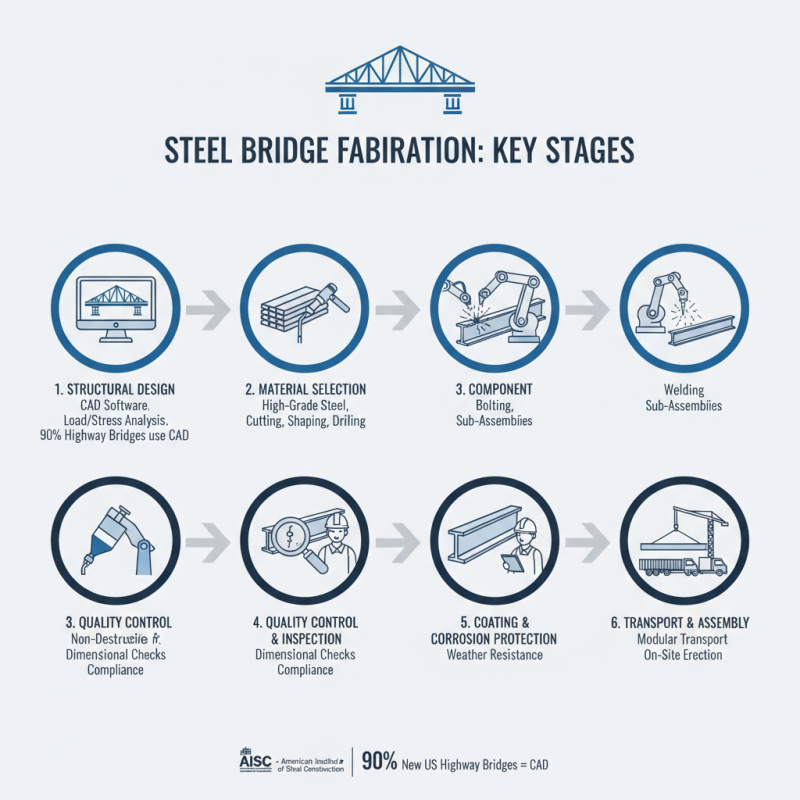

Steel bridge fabrication is a complex process that involves several key stages, from initial design to final assembly. The process begins with detailed structural design, where engineers utilize advanced software to create precise models that account for the loads and stresses the bridge will encounter. According to a report by the American Institute of Steel Construction, nearly 90% of all new highway bridges are designed using computer-aided design (CAD) technology, enhancing accuracy and efficiency in the preliminary phases.

Following the design, steel is selected and prepared, typically involving cutting and shaping using modern techniques such as plasma cutting or CNC machining. This phase is critical, as the right material selection and fabrication can significantly influence the longevity and safety of the bridge. Research from the National Steel Bridge Alliance indicates that bridges fabricated with high-strength steel can reduce the overall weight without compromising structural integrity, often leading to savings in both material costs and installation time.

Tips: Collaborating closely with structural engineers and fabricators during the design phase can streamline the fabrication process and help identify potential challenges early on. Additionally, utilizing innovative construction technologies, like modular assemblies, can improve efficiency and accelerate project timelines significantly. Engaging specialized consultants early in the project can also pave the way for a smoother assembly phase, ensuring all components fit together seamlessly.

Steel bridge fabrication offers numerous benefits, particularly when it comes to cost efficiency and durability. One of the primary advantages of this method is its ability to streamline the construction process. Prefabricating steel components in a controlled environment allows for faster assembly on-site, reducing labor costs and minimizing project timelines. Furthermore, steel's inherent strength and resistance to various environmental factors ensure that bridges constructed using steel will endure rigorous use over time, reducing the frequency and costs associated with repairs and maintenance.

Additionally, prefabricated steel bridges can be highly cost-effective due to fewer raw materials needed and lower waste generation during the manufacturing process. The use of advanced technology in fabrication can also lead to precise engineering, thereby optimizing material usage and structural integrity. This approach not only translates to short-term savings but also provides long-term value through increased lifespan and reduced maintenance needs.

Tips for maximizing the benefits of steel bridge fabrication include investing in high-quality design software to enhance the precision of pre-assembly plans. Additionally, collaborating with experienced fabricators can ensure that the project adheres to safety and quality standards, further enhancing the durability of the result. Lastly, regular inspections and maintenance, even for robust steel structures, can extend the lifespan of the bridge and sustain its cost efficiency over many years.

Steel bridge fabrication is undergoing a significant transformation with a growing emphasis on sustainability. The environmental impact of fabrication processes has led many companies to adopt practices that minimize waste and reduce carbon footprints. According to the American Institute of Steel Construction (AISC), steel produced with recycled content can lead to a reduction in energy consumption by up to 75% compared to traditional steel production methods. This shift not only enhances the sustainability of steel bridges but also positions them as a more eco-friendly option for infrastructure development.

One innovative approach in steel bridge fabrication is the incorporation of advanced technologies such as 3D modeling and automated welding. These technologies not only improve the precision of fabrication but also enhance material efficiency, reducing excess waste. A report from the Steel Construction Institute (SCI) highlights that using computer-aided design (CAD) in bridge fabrication can reduce material waste by up to 10%. Additionally, embracing modular construction techniques allows for on-site assembly, which minimizes transportation emissions and further contributes to sustainable practices.

Tips for implementing sustainable practices in steel bridge fabrication include prioritizing the selection of recycled materials, utilizing energy-efficient machinery, and striving for local sourcing to reduce transportation impacts. Furthermore, engaging in continuous training for workers to adopt sustainable methods can create a culture of environmental responsibility within organizations. By adopting these practices, companies not only contribute positively to the planet but also gain competitive advantages in a growing market that values sustainability.