In the rapidly evolving landscape of the construction industry, the significance of steel fabrication and installation has become increasingly paramount for ensuring project success. According to a report by the American Institute of Steel Construction, steel structures account for over 60% of all commercial and industrial buildings erected annually in the United States. This stark statistic highlights the material’s dominance in modern building practices and underscores the necessity of proficient fabrication and meticulous installation processes to meet industry standards and safety regulations.

Expert in structural engineering, Dr. Emily Johnson, emphasizes the pivotal role of "steel fabrication and installation" in driving project efficiency and integrity. She states, “The precision achieved through advanced fabrication techniques translates into better performance on site, reducing delays and enhancing safety.” As projects grow in complexity, the demand for skilled labor and innovative solutions in the steel fabrication sector has become more pronounced, enabling builders to harness the full potential of steel's strength and versatility.

Ultimately, an investment in quality steel fabrication and installation not only solidifies a project's structural foundation but also serves as a catalyst for long-term sustainability. By prioritizing these essential components, stakeholders can ensure that their construction endeavors are built on a solid framework of reliability and innovation.

Steel fabrication plays a pivotal role in modern construction projects, serving as the backbone of structural integrity and design flexibility. With the increasing complexity of architectural designs, the demand for customized steel components has surged. Steel’s versatility allows architects and engineers to push creative boundaries, enabling the construction of iconic structures that not only meet functional requirements but also enhance aesthetic appeal. The ability of steel to be shaped, welded, and assembled into intricate frameworks makes it an indispensable material in contemporary building practices.

Moreover, the precision involved in steel fabrication significantly reduces construction time while ensuring quality control. Prefabricated steel components can be manufactured off-site under controlled conditions, which minimizes delays caused by weather or site-related issues. When these components arrive at the construction site, they can be swiftly installed, allowing for faster project completion without compromising safety or reliability. By integrating steel fabrication into the construction process, project managers can streamline workflows, optimize resource allocation, and ultimately achieve project milestones more efficiently.

Steel installation plays a critical role in modern construction, offering numerous advantages that contribute significantly to the success of building projects. One of the primary benefits of utilizing steel in construction is its superior strength-to-weight ratio. This characteristic allows for lighter structures without compromising on stability and durability. As a result, architects and engineers can design taller buildings and expansive spaces while minimizing the overall material needed, leading to cost savings in both materials and transportation.

Another advantage of steel fabrication and installation is the speed of construction. Steel components can be pre-fabricated off-site, significantly reducing on-site labor times. This efficiency allows projects to be completed faster, enabling developers to meet deadlines and reduce the time to market for new buildings. Additionally, steel’s resistance to various environmental factors, such as pests and fire, enhances the longevity of structures, ensuring that investments are protected for years to come. Overall, integrating steel into construction not only elevates structural integrity but also streamlines construction processes, cementing its status as an essential material in modern architecture.

| Advantage | Description | Impact on Construction |

|---|---|---|

| Durability | Steel structures are resistant to harsh weather conditions and corrosion. | Increases lifespan and reduces maintenance costs. |

| Cost-Effectiveness | Initial fabrication cost can be high, but leads to lower overall costs. | Saves money over time through durability and reduced repairs. |

| Speed of Construction | Factory-fabricated components allow for faster on-site assembly. | Reduces time to completion, allowing for quicker occupancy. |

| Design Flexibility | Steel can be molded into various shapes and sizes. | Enables innovative architectural designs. |

| Sustainability | Steel is recyclable and can be reused in future projects. | Supports green building initiatives and reduces waste. |

Quality control processes in steel fabrication and installation are paramount to ensuring the longevity and safety of construction projects. According to a report by the American Institute of Steel Construction, around 40% of project delays are attributed to structural defects that arise from inadequate quality control measures. Effective quality management not only mitigates these risks but also significantly improves overall project efficiency. By implementing rigorous inspection protocols, such as weld testing and dimensional verification, companies can identify potential issues early in the fabrication process, thus reducing rework and associated costs.

Moreover, adherence to established quality standards, such as those set by the International Organization for Standardization (ISO), has shown to enhance the reliability of steel structures. Data from the Steel Construction Institute suggests that projects following strict quality control guidelines see a 20% increase in on-time delivery compared to those that do not. This strengthens the case for investing in comprehensive quality control measures, as they not only protect the structural integrity of buildings but also facilitate smoother project execution, fostering trust and credibility among stakeholders in the construction industry. The combined impact of these processes underscores the critical role that quality control plays in the success of steel fabrication and installation.

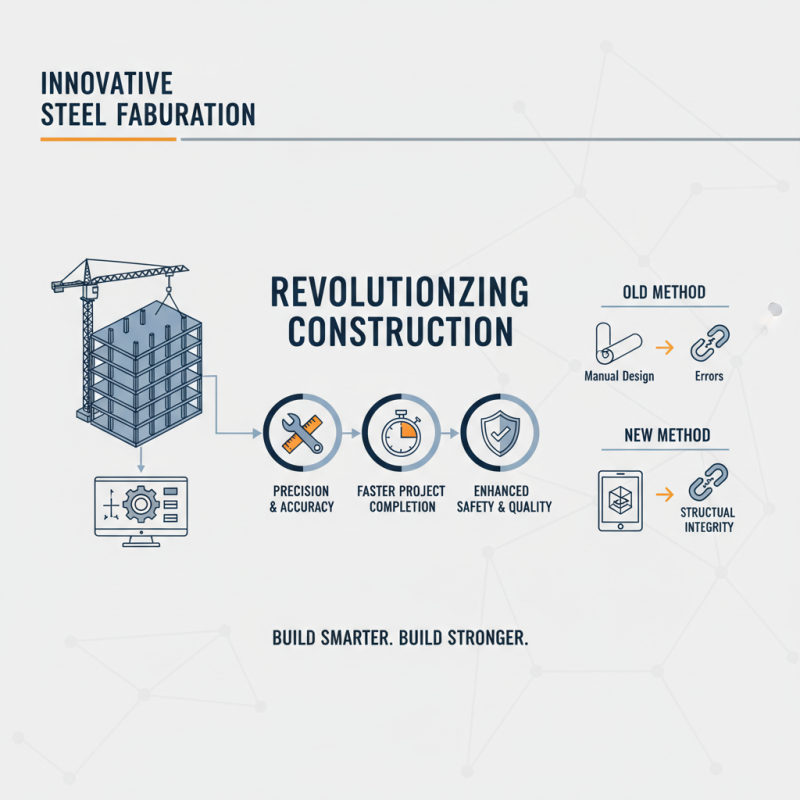

Innovative techniques in steel fabrication are revolutionizing the construction industry, promoting higher efficiency and enhancing structural integrity. One of the most notable advancements is the integration of computer-aided design (CAD) technology, which allows for precision in measurements and accuracy in components. This technology enables engineers and architects to create detailed 3D models of steel structures, reducing the margin for error during both the fabrication and installation processes. As a result, projects can be completed faster while maintaining a high level of quality and safety.

Additionally, the use of automated fabrication processes has dramatically increased the speed of production. Robotics and advanced machinery can cut, weld, and assemble steel components with minimal human intervention, ensuring consistency and reducing the likelihood of costly mistakes. Lean manufacturing principles further enhance this efficiency by minimizing waste and optimizing workflow. These innovative techniques not only lead to significant time savings but also help in managing costs effectively, making steel fabrication a cornerstone of successful construction projects.

In the realm of construction, the collaboration between engineers and fabricators is crucial for the successful execution of projects. Engineers are tasked with designing structures that meet safety codes and functional requirements, while fabricators bring these designs to life through skilled craftsmanship and advanced manufacturing techniques. This partnership ensures that the vision outlined in the blueprints translates seamlessly into reality, where both aesthetic appeal and structural integrity are maintained.

Effective communication is imperative in this collaborative process. Engineers must relay their specifications clearly, and fabricators should provide feedback regarding the feasibility of these designs from a manufacturing standpoint. This ongoing dialogue helps to identify potential challenges early on, allowing for adjustments and preventing costly delays. Furthermore, involvement of fabricators during the design phase can lead to innovative solutions that enhance efficiency, reduce waste, and ultimately lead to more successful project outcomes. Through their combined expertise, engineers and fabricators create a synergy that not only improves project viability but also elevates the overall quality of construction.