Stainless steel fabrication is a crucial process in many industries, from construction to automotive. The unique properties of stainless steel make it a popular choice for various applications. However, achieving successful results requires a keen understanding of fabrication techniques.

In this article, we will explore ten practical tips to enhance your stainless steel fabrication skills. These tips aim to improve efficiency while maintaining high-quality standards. Each technique reflects common challenges encountered in the field, emphasizing the importance of continuous improvement. Mistakes often happen, and acknowledging them can lead to better results.

Effective stainless steel fabrication not only depends on skills but also on the right tools and practices. Paying attention to details, such as cutting precision and welding techniques, is vital. The journey of mastering stainless steel fabrication is ongoing, filled with lessons and growth opportunities. Each project brings new challenges, encouraging reflection and adaptation.

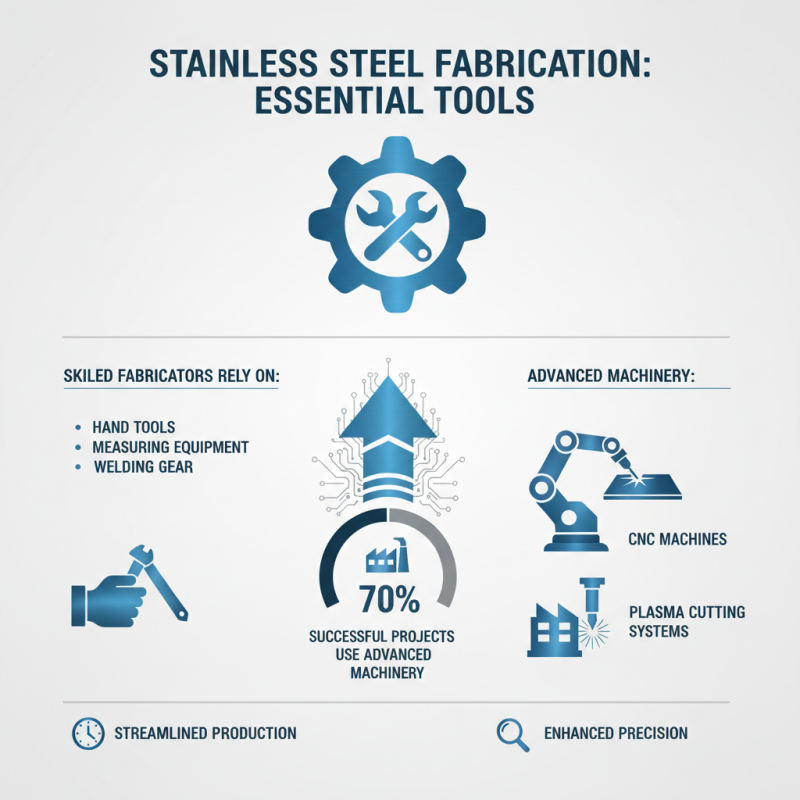

When it comes to stainless steel fabrication, the right tools and equipment are essential. Skilled fabricators rely on various essential tools to produce high-quality products. According to a recent industry report, about 70% of successful projects utilize advanced machinery like CNC machines and plasma cutting systems. These machines streamline production and enhance precision.

Additionally, hand tools play a critical role. Items such as angle grinders, welders, and sheet metal shears are vital for on-site adjustments. High-quality personal protective equipment is also necessary. Fabricators stress that safety gear, such as gloves and eye protection, should never be overlooked. These tools help minimize risks but can be underappreciated.

Not all projects go as planned. Equipment failures can cause delays and increase costs. Regular maintenance is essential for longevity. A survey indicated that 45% of companies faced downtime due to neglected tools. Remaining proactive can prevent these setbacks. Each piece of equipment needs careful consideration, as it impacts the final product's quality. In the end, investing in the right tools can lead to significantly better outcomes in stainless steel fabrication.

Understanding the properties of stainless steel can significantly improve fabrication outcomes. Stainless steel is renowned for its corrosion resistance, durability, and aesthetic appeal. According to a report from the International Stainless Steel Forum, the market for stainless steel products has been growing steadily, presenting opportunities for fabricators.

Key characteristics include high tensile strength and workability. However, fabricators often overlook optimal temperature ranges during welding. For instance, welding at temperatures that are too high can cause the material to lose its intended properties. This lapse can lead to joint failures, affecting the overall quality of the product.

Another critical aspect is the passivation process, which enhances corrosion resistance. Neglecting this step can lead to premature rusting, thus compromising project integrity. A study indicated that 30% of fabricators do not fully understand the importance of proper finishing techniques. These oversights can negatively impact the performance and longevity of stainless steel components in various applications.

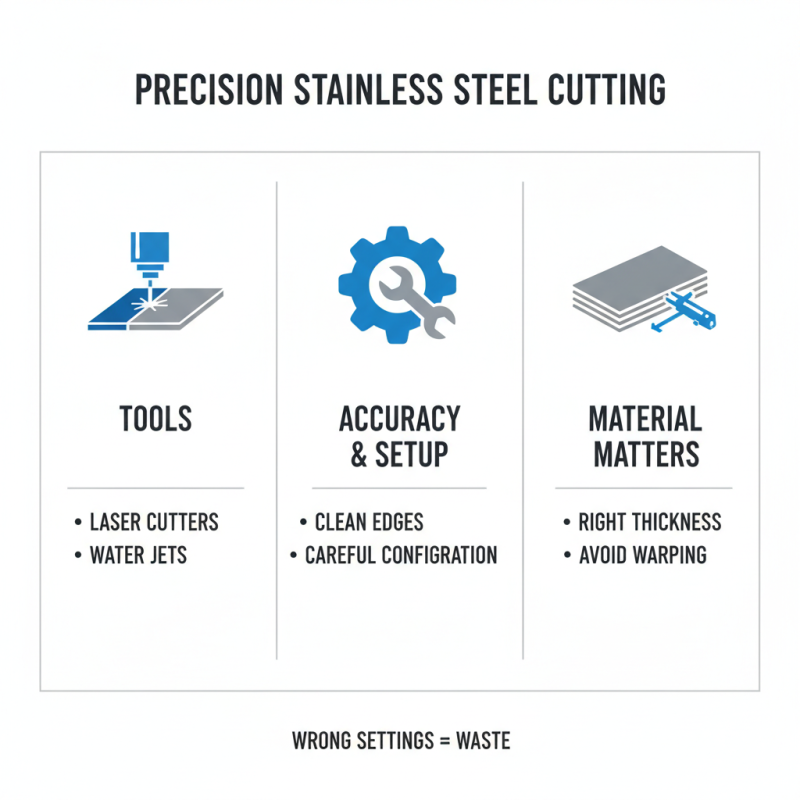

When it comes to cutting and shaping stainless steel, precision is crucial. Utilizing tools like laser cutters or water jets can provide clean edges. Both tools offer high accuracy but may require careful setup. Wrong settings can lead to material waste or unsatisfactory results. Using the right thickness of steel is essential, as too thin may warp during the process.

Shearing is another technique worth considering. It involves using a shear to create straight cuts. However, it can sometimes produce rough edges. Proper finishing techniques, like grinding or sanding, can help. Observing the edge after cutting is critical. If it’s not smooth, adjustments are needed. Take time to troubleshoot and refine your methods.

Bending stainless steel needs attention too. A press brake can shape metal accurately, but over-bending is a common issue. This can damage the material and cause stress points. It’s beneficial to conduct test bends first. Check the angle and finish before moving to final pieces. Remember, attention to detail in these methods will lead to better outcomes in the end.

When it comes to stainless steel fabrication, choosing the right welding methods is crucial. TIG welding is a popular choice. It offers precision and a clean finish, making it great for thin materials. However, it requires skill and practice. If you’re just starting, it may feel daunting.

MIG welding is another good option. It's faster and easier for beginners. You can weld thicker pieces with ease. Still, the finish may not be as smooth as TIG. Some practitioners find this technique very forgiving, yet others struggle with consistency.

To ensure successful fabrication, consider these tips. Always clean the surfaces before welding. Contaminants can lead to weak joints. Use a backing bar to improve weld penetration. Ensure proper setup—torch angle and speed matter. Your technique can improve with time, but don't rush the learning process. Each project is a chance to refine your skills. Engage with other fabricators to gain valuable insights.

Finishing and polishing stainless steel surfaces can significantly enhance their appearance and durability. Start by selecting the right tools for the job. A wire brush can remove surface contaminants. For a smoother finish, consider using a random orbital sander with appropriate grit. Don't rush this step. Take your time; it pays off later.

After sanding, move to polishing. Use a polishing compound with a soft cloth for a refined look. Ensure you apply even pressure to avoid uneven surfaces. Imperfections may still linger. It’s crucial to inspect your work closely. Sometimes, a second round of polishing is necessary to achieve the desired shine.

Finally, remember the importance of cleanliness. Dust and debris can mar a perfect surface. Keep your workspace clear and organized. Each step you take in refining stainless steel counts. Mistakes can happen, and learning from them will improve your technique. Embrace the process; perfection often lies in the details.