In the realm of industrial applications, heavy steel plate fabrication plays a vital role. It is essential for constructing robust structures and machinery. Various techniques have emerged, each with unique advantages and challenges.

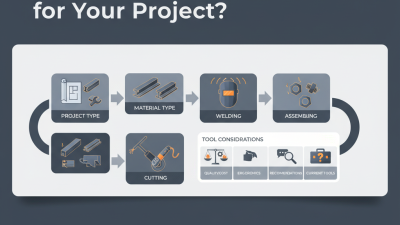

Understanding these methods can significantly impact efficiency and quality. Weldments, cutting systems, and surface treatments all come into play. The choice of technique often depends on project requirements and material specifications. Sometimes, techniques may not yield the expected results, leading to rework or wastage.

Navigating through these heavy steel plate fabrication methods requires careful consideration. Each option has its merits and drawbacks. A thorough grasp of these aspects can ensure optimal performance and durability in industrial projects. It's crucial to assess the practicality of different techniques for specific needs.

Heavy steel plate fabrication plays a crucial role in industrial settings. It is used in construction, shipbuilding, and manufacturing. These plates provide strength and durability in various applications. However, the process can be complex and requires careful attention.

When working with heavy steel plates, proper handling is vital. Any mistake can lead to defects or damage. Ensure that your workspace is organized. A clean area reduces errors. Use appropriate lifting equipment to avoid injuries. Ensure that the plates are stored correctly to prevent warping.

Tips: Always inspect your equipment before starting. Safety gear is necessary for anyone involved in the fabrication process. Regular maintenance of tools can prevent unexpected breakdowns.

Understanding thermal cutting techniques is essential too. Techniques such as plasma cutting can enhance precision. However, they require training for effective execution. Taking shortcuts may lead to poor-quality fabrication. Always follow the recommended guidelines.

Tips: Practice on scrap materials before actual production. This will help in mastering the techniques. Pay attention to detail; it often makes the difference between success and failure.

Cutting heavy steel plates is a critical process in industrial fabrication. The efficiency of this process can significantly impact production costs and project timelines. According to a report from TechSci Research, the global steel plate market is expected to grow at a rate of 5.6% through 2025. This growth highlights the increasing demand for faster and more efficient cutting techniques.

One commonly used method is plasma cutting. It utilizes high-temperature plasma to slice through steel plates quickly. This technique can cut plates up to 80 millimeters thick. Another technique is laser cutting, known for its precision. It can produce intricate designs with minimal material waste. A study from MarketsandMarkets suggests that the laser cutting segment alone will reach $4 billion by 2027. However, despite its advantages, laser cutting can be costly and may not be suitable for all applications.

Waterjet cutting represents another viable option. It uses high-pressure water mixed with abrasive substances. This method can cut various materials without generating heat-affected zones. However, it often requires more maintenance, which can lead to higher long-term costs. Each cutting technique has its pros and cons, often requiring careful consideration to achieve the best results in heavy plate fabrication.

| Technique | Description | Advantages | Typical Applications |

|---|---|---|---|

| Plasma Cutting | A process that uses a plasma torch to cut thick metal sheets. | High speed, good precision, versatility in thickness. | Fabrication of structural components, automotive parts. |

| Laser Cutting | Uses focused laser beams to cut through metal. | Exceptional precision, minimal heat-affected zone. | Aerospace components, intricate designs. |

| Oxy-Fuel Cutting | Combines oxygen and fuel gas to produce a flame for cutting. | Cost-effective, capable of cutting very thick materials. | Heavy machinery, construction applications. |

| Waterjet Cutting | Utilizes high-pressure water jets mixed with abrasive materials to cut. | No thermal distortion, can cut a variety of materials. | Art, signage, diverse material applications. |

| Bandsaw Cutting | Involves a continuous band of metal with teeth for cutting. | Good for curves and shapes, quieter operation. | Pipe and structural component production. |

Welding techniques play a crucial role in the fabrication of heavy steel plates. These processes ensure strong, durable, and reliable assemblies. Common methods include MIG welding, TIG welding, and stick welding. Each technique has its strengths, but none is without challenges.

MIG welding is popular due to its speed. It effectively joins thick plates with less heat distortion. However, it's not always suitable for all positions. Sometimes, achieving the right angle can be tricky. On the other hand, TIG welding offers excellent control. It's great for thinner materials but can be slower. Precision is key, making it at times frustrating for large applications.

Stick welding remains a go-to for outdoor projects. It performs well in windy conditions. Yet, its cleanup can be tedious. Welds might require more grinding to achieve a smooth finish. Choosing the right welding technique depends on the specific application and environment. Industrial applications demand a balance between speed and quality. Each method presents distinct advantages and requires careful consideration to select the most fitting approach.

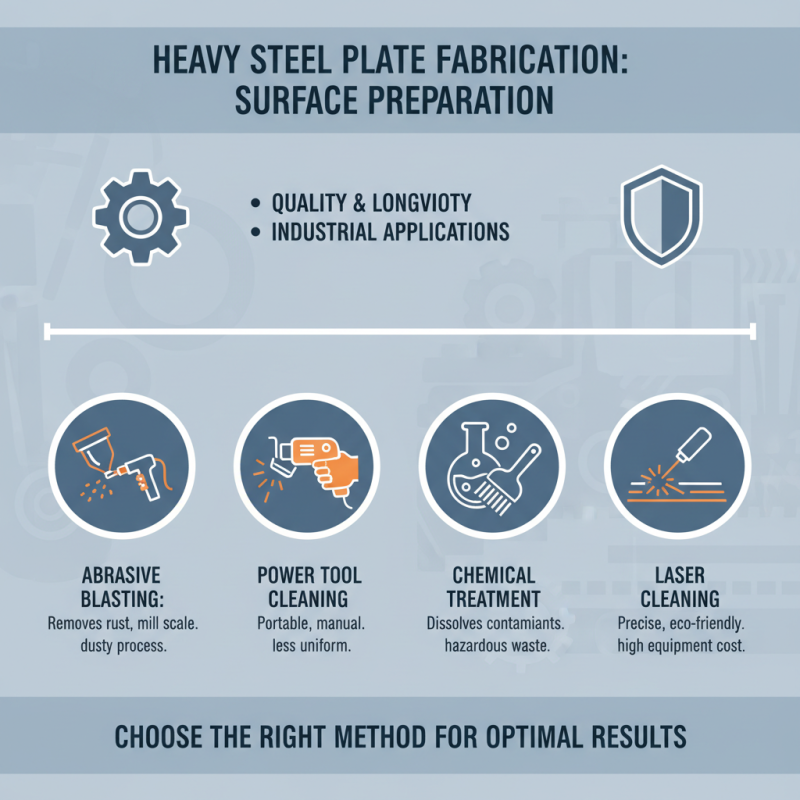

Surface preparation is crucial in heavy steel plate fabrication. Proper preparation ensures quality and longevity in industrial applications. Different methods exist, and each has its strengths and weaknesses.

A common technique is abrasive blasting. This method removes contaminants and rust. The result is a clean surface ideal for welding or coating. However, it can be messy. Dust can spread, leading to environmental concerns. Ensure proper containment measures.

Chemical cleaning is another method. It uses solvents to degrease surfaces. It is effective at removing oil and grease. Yet, it may not always eliminate rust completely. Be mindful of potential chemical hazards. Always wear appropriate protective gear.

Tips: Always inspect the surface after cleaning. Look for imperfections or residue. Rinse thoroughly to avoid chemical buildup. Every method has limitations. Consider your specific project needs and conditions. Reflections on the chosen method can lead to better results.

Heavy steel plate fabrication plays a crucial role in industrial applications. Quality control measures are essential to ensure the reliability of finished products. According to a recent industry report, about 30% of fabricated steel components failed to meet quality standards in the past year. This highlights the need for robust inspection protocols.

One effective quality control measure is the implementation of ultrasonic testing. This technique can detect internal flaws in steel plates. Another important approach is visual inspection, which helps identify surface defects. Combining these methods can lead to a significant reduction in failure rates. For example, companies that adopted strict quality control saw a 15% decrease in rejected products.

Tips: Regular training for employees is vital. Well-informed staff can spot potential issues early. Moreover, maintaining equipment standards is critical. It’s also beneficial to document every step for accountability. Inefficient processes can lead to costly mistakes. Reflecting on past projects can unveil areas for improvement.