In the competitive world of steel fabrication and installation, achieving success requires not just skill but also the right techniques. According to a report by the American Institute of Steel Construction, the industry has seen a substantial growth rate of 7% over the past five years. This growth highlights the importance of efficiency in fabrication and installation processes.

Jerry H. Davis, a renowned expert in the field, states, "Adopting innovative techniques in steel fabrication and installation can drastically reduce project timelines." His words reflect a critical need for industry players to adapt. Many companies struggle with outdated practices and inefficient workflows. This leads to lost time and increased costs.

Moreover, the integration of modern technology, such as BIM and automation tools, is vital. These tools can enhance precision and consistency. However, not all organizations embrace these advancements. Some resist change, which can hinder progress. Reflecting on these trends is essential for all stakeholders. Embracing the best practices can pave the way for success in this evolving industry.

Steel fabrication is the process of creating structures from raw steel. This involves cutting, bending, and assembling steel components. Techniques used in fabrication can influence the overall efficiency and success of a project. Understanding these processes is essential for anyone in the construction industry.

Effective steel fabrication starts with planning. It's crucial to have precise blueprints. Poor design can lead to costly errors. Communication among team members is vital. Everyone needs to be on the same page. A small oversight in measurements can cause significant delays. Always double-check calculations.

When it comes to installation, using the right tools is essential. Ensure that you have the machinery suited for your needs. Lifting equipment must be properly rated and maintained. Safety is paramount. Train all workers on the equipment. Regular safety drills can help. A cautious approach minimizes risks. Don’t overlook the importance of quality control during the installation phase. Each component should be inspected for defects. A flaw can compromise the entire project.

Craftsmanship matters. Keep a watchful eye on workmanship and detail. Learning from mistakes is part of the growth process. Reflecting on past projects can guide improvements. Each job brings its own lessons. Embrace them, and strive for better results in future projects.

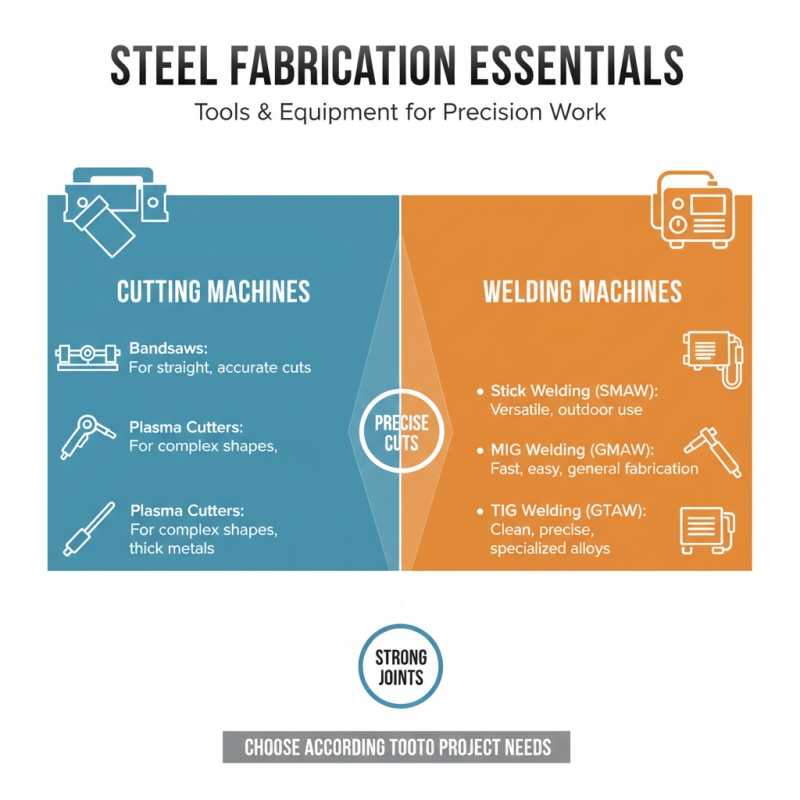

When it comes to steel fabrication, having the right tools and equipment is crucial. Invest in high-quality cutting machines. Bandsaws and plasma cutters can make precise cuts. A good welding machine is essential for joining materials. Stick, MIG, and TIG welding machines each have specific applications. Choose according to your project needs.

Don’t forget about safety gear. Proper gloves, helmets, and eye protection are a must. They protect against sparks and metal shards. Also, ventilation equipment is vital. Fumes from welding can be harmful. Always ensure proper air circulation in your workspace.

Tips: Regularly inspect your tools for damage. Dull blades or faulty equipment can lead to errors. Keep your workspace organized. An uncluttered area reduces the risk of accidents. Finally, practice makes perfect. Experimentation is key. Mistakes will happen, but learning from them is important in mastering steel fabrication techniques.

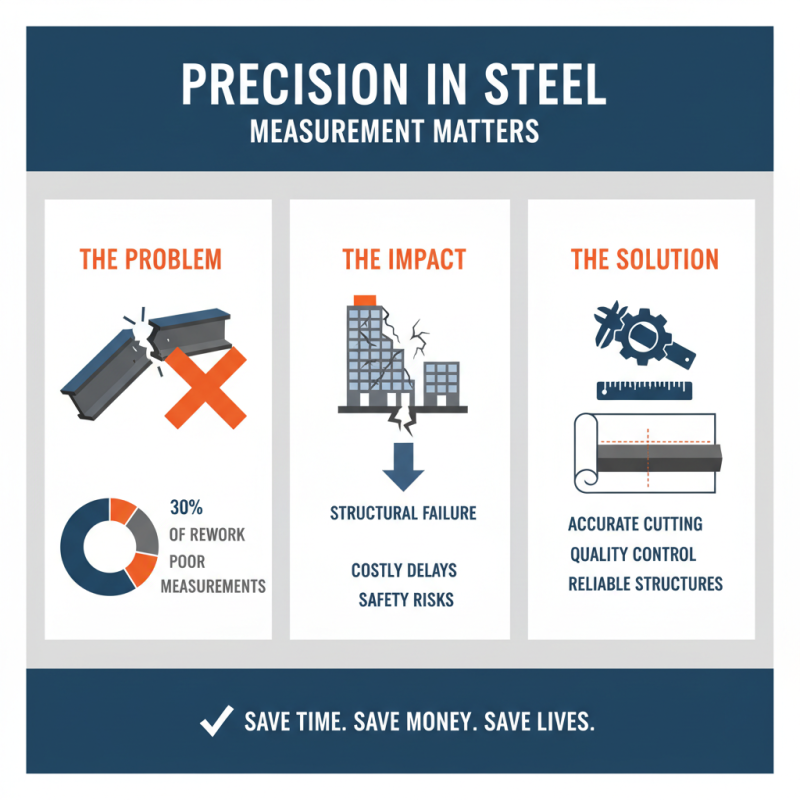

Accurate measurement and cutting are critical in steel fabrication and installation. A survey by the American Institute of Steel Construction indicated that poor measurements lead to about 30% of rework in projects. This underlines the importance of precision. Installing improperly measured steel can cause structural failures, resulting in significant consequences.

Techniques such as utilizing laser measuring tools can greatly enhance accuracy. These tools allow for quick and precise measurements, reducing the margin for error. Also, employing CAD software aids in visualizing the design before cutting begins. However, not all fabricators adapt rapidly to these technologies. Resistance to change remains a challenge in some traditional settings, affecting overall efficiency.

On the cutting side, water jet cutting and plasma cutting are popular methods. Water jet cutting is known for its precision, with an average tolerance of ±0.005 inches. Yet, it is less widely available compared to plasma cutting, which can create rough edges that require additional finishing. Many installations overlook this detail, leading to an incomplete final product. Reflecting on these techniques could shed light on areas needing improvement while driving quality in steel installation.

Welding is a fundamental aspect of steel fabrication. Different projects call for specific welding methods. Choosing the right technique can make or break your project. According to a recent industry report, 30% of welding failures are due to improper technique selection.

MIG welding is popular for its speed and versatility. It’s ideal for projects requiring thin materials. However, beginners can struggle with technique. This can lead to issues like poor penetration and undercuts. TIG welding, on the other hand, excels in providing precision. It’s excellent for thinner metals and offers strong control. Yet, it demands a higher skill level. Many find it difficult to master.

Stick welding remains a staple in heavy-duty applications. It’s reliable, but the process can be messy. Spatter and cleanup consume time and resources. An industry study suggests that 15% of projects experienced setbacks due to welding cleanup. Understanding these challenges can lead to better decisions in your fabrication processes. Each method has its advantages and faults. Evaluating your project’s specific needs is essential for success.

Quality control in steel fabrication and installation is crucial. It ensures that structures meet safety and performance standards. Implementing best practices can significantly improve outcomes. One effective method is conducting regular inspections. These inspections help identify defects early. Small issues, if ignored, can escalate into major problems.

Another important aspect is training workers. Skilled workers are more likely to recognize potential issues. They understand the nuances of materials and techniques. Yet, many companies overlook ongoing training. This gap can lead to mistakes that are hard to fix later.

Documentation is also essential. Keep detailed records of all processes. This can include weld maps and fabrication logs. It allows for better traceability and accountability. Without proper documentation, finding the source of a problem can be challenging. Sometimes, mistakes go unnoticed until it's too late. Establishing a culture of quality is vital. Encourage feedback and continuous improvement. This mindset can transform a project from good to great.

| Technique | Description | Benefits | Quality Control Measures |

|---|---|---|---|

| Laser Cutting | Utilizes laser technology for precise cuts. | High precision, minimal material waste. | Regular calibration of machines. |

| Welding Techniques | Different methods like MIG and TIG for joining metals. | Strong joints, versatile applications. | Visual inspections and destructive testing. |

| Quality Material Selection | Choosing the right type of steel for the project. | Improved durability and performance. | Material certification and testing. |

| Pre-fabrication | Assembly of components off-site. | Efficiency and reduced on-site labor. | Inspection of modules before delivery. |

| Robotic Automation | Automated processes for fabrication. | Consistency and reduced human error. | Regular software updates and maintenance. |

| Surface Treatment | Processes such as galvanization for protection. | Enhanced longevity and corrosion resistance. | Adherence to environmental standards. |

| Project Management | Effective scheduling and resource allocation. | Minimized delays and cost overruns. | Regular progress tracking and reporting. |

| Field Measurements | Accurate measurements on site before installation. | Reduced errors and rework. | Verification against design specifications. |

| Documentation and Reporting | Keeping detailed records of processes and outcomes. | Traceability and accountability. | Routine audits of documentation. |

| Safety Protocols | Implementing safety measures during fabrication. | Prevention of workplace accidents. | Regular safety drills and evaluations. |