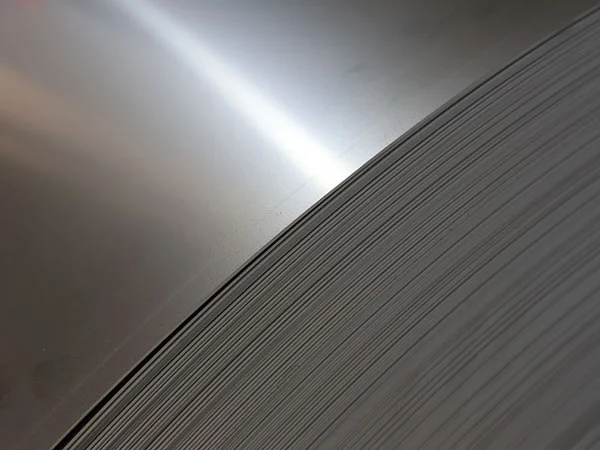

Ningbo Jilian Steel Co., Ltd is a leading supplier of SUS 310s High Temperature Alloy Coil for Heat Exchangers in China. Besides, we also provide precision stainless steel coils, including 301, 304, 304L, 316L, 430, 410s, 904L. We warmly welcome business partners from international markets to collaborate sincerely for mutual success.

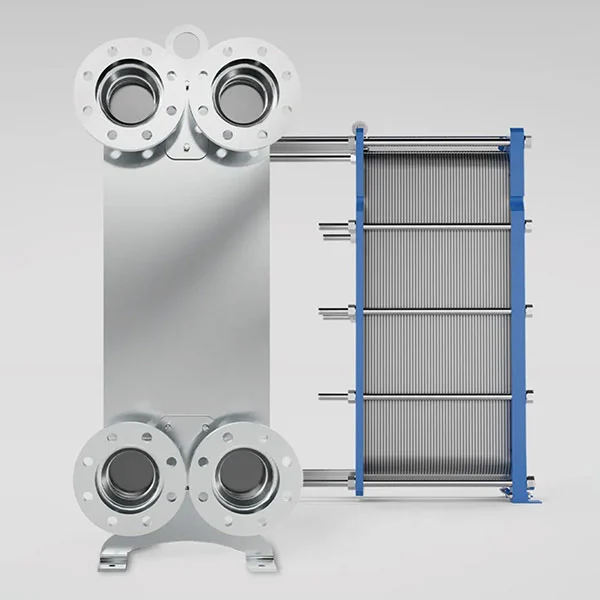

SUS 310s high temperature alloy coil for heat exchangers is an austenitic chromium-nickel stainless steel, which is characterized by excellent high temperature resistance and excellent oxidation resistance. By increasing the chromium and nickel content, 310S stainless steel can maintain its mechanical strength and corrosion resistance in high temperature environments, and can work stably even under high temperatures of intermittent heating to 1150°C or continuous heating to 1100°C. This makes it an ideal material for high temperature applications, especially in heat exchanger manufacturing.

| GRADE | Chemical Composition | ||||||

| C | Si | Mn | P | S | Ni | Cr | |

| % | % | % | % | % | % | % | |

| 310S | ≤0.08 | ≤1.05 | ≤2.00 | ≤0.045 | ≤0.030 | 19.00/22.00 | 24.00/26.00 |

The excellent high temperature resistance of SUS 310s high temperature alloy coil for heat exchangers is mainly reflected in its excellent oxidation resistance and creep resistance at high temperatures, which can effectively resist the erosion of high temperature gas and flame, and ensure the stable operation of the heat exchanger under high temperature conditions.

The high chromium and nickel content gives 310S stainless steel coil excellent corrosion resistance, which can resist corrosion from a variety of media, including high temperature gas, water vapor and some chemicals, and prolong the service life of the heat exchanger.

Even in high temperature environments, 310S stainless steel coil can still maintain good strength and toughness, ensuring the stability and safety of the heat exchanger structure.

Jilian Steel's 310S stainless steel coil has good formability and weldability, which facilitates heat exchanger manufacturers to carry out complex structural design and efficient production and manufacturing.

We strictly control the chemical composition of 310S stainless steel coils to ensure the stability and consistency of material properties, and provide guarantees for the long-term and reliable operation of heat exchangers.

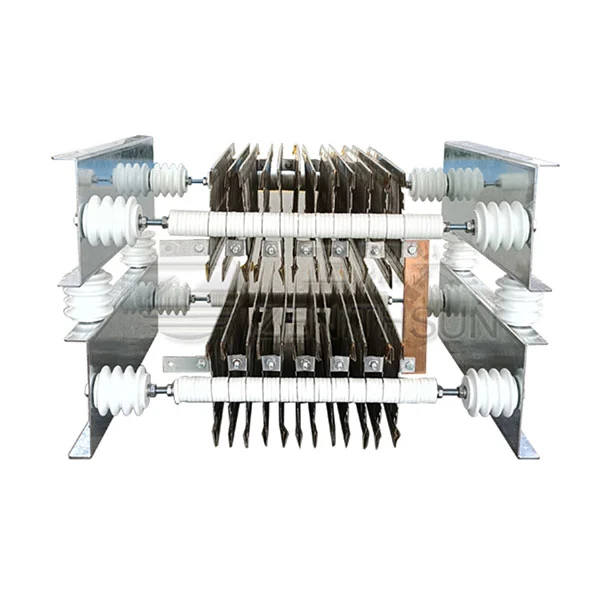

SUS 310s high temperature alloy coil for heat exchangers are widely used in various types of high-temperature heat exchangers, including industrial furnace heat exchangers, power plant heat exchangers, chemical and petrochemical industry heat exchangers, metallurgical industry heat exchangers, waste heat boilers for waste incineration, solar thermal power generation, etc.

The SUS 310s high temperature alloy coil for heat exchangers has high accuracy, with thickness tolerances as tight as +/-0.002mm. It has 2B, BA, 2BA and more surface finish. The surface we produce are flawless, scratch-free, which it is best choice for applications that demand the highest quality.

As for packaging details, there are standard packaging (waterproof paper and steel belt packing) and wooden box packaging, as well as customized packaging solutions.

Our dedicated loading team ensures meticulous handling of every shipment. Each container is securely reinforced with wood and wire rope to guarantee that your goods ( SUS 310s high temperature alloy coil for heat exchangers) arrive in safe condition.

Certificates: ISO9001, SGS, MTC...